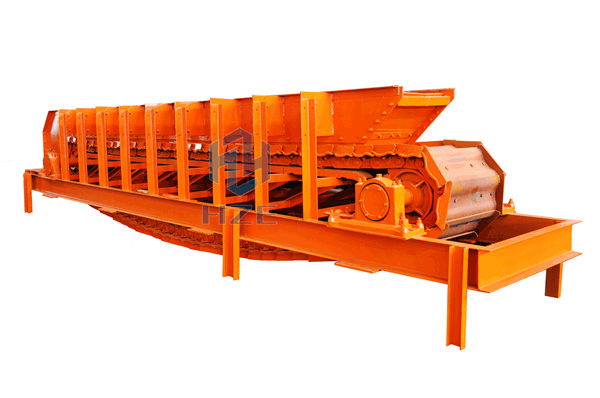

Apron Feeder

Working Principle

Apron feeder consists of drive wheel device, tail wheel tension device, endless belt made up of flat overlapping steel plates, chain transmission device and driving device. Every steel plate is assembled together to form a complete line of plates which is carried on two roller chains, one in each side. During the operation of the apron feeder, the traction chains of the chain transmission device engage with the sprocket to drive the endless belt to move along the longitudinal center-line. The material discharged from the ore bin is transported along the conveying line to the front of the feeder for continuous and uniform feeding.

Features

The endless belt is made of the wear-resistant steel plates with high strength and stiffness to withstand great impact.

Standard track chain, no lubrication or deviation, for interchangeability and long service life.

The sprockets are made of high strength alloy steel and quenched, which has excellent wear resistance.

Equipped with composite spring on the tail of the frame, which can effectively buffer the impact load of the chain.

Segmented drive sprockets, easy to maintain without removing the chain plate.

Traction chain and load chain are separated, so the dynamic load is small to extend life.

The bottom surface of the endless belt is equipped with a scrapper to reduce the stickly materials.

The speed can be adjusted by the frequency converter for energy saving and easy control, convenient feeding adjustment and uniform feeding.

Suitable for transporting high humidity and viscous materials.

Application

It is used for continuously feeding materials from ore bin to primary crusher of large crushing plant. It can also be used for short-distance transporting or transporting materials with large specific gravity.

Technical Parameters

Heavy Duty and Small Size

|

Model |

Belt Plates |

Feeding Size (mm) |

Capacity |

Power (kW) |

||

|

Belt Width |

Center Distance of sprockets (mm) |

Speed |

||||

|

GBZ120-4.5 |

1200 |

4500 |

Adjusted |

≤500 |

100 |

15 |

|

GBZ120-5 |

5000 |

|||||

|

GBZ120-5.6 |

5600 |

|||||

|

GBZ120-6 |

6000 |

|||||

|

GBZ120-8 |

8000 |

22 |

||||

|

GBZ120-8.7 |

8700 |

|||||

|

GBZ120-10 |

10000 |

|||||

|

GBZ120-12 |

12000 |

|||||

|

GBZ120-15 |

15000 |

30 |

||||

Heavy Duty and Medium Size

|

Model |

Belt Plates |

Feeding Size (mm) |

Capacity |

Power (kW) |

||

|

Belt Width |

Center Distance of sprockets (mm) |

Speed |

||||

|

GBZ150-4 |

1500 |

4000 |

Adjusted |

≤600 |

150 |

15 |

|

GBZ150-6 |

6000 |

22 |

||||

|

GBZ150-7 |

7000 |

|||||

|

GBZ150-8 |

8000 |

|||||

|

GBZ150-9 |

9000 |

30 |

||||

|

GBZ150-12 |

12000 |

45 |

||||

Heavy Duty and Big Size

|

Model |

Belt Plates |

Feeding Size (mm) |

Capacity |

Power (kW) |

||

|

Belt Width |

Center Distance of sprockets (mm) |

Speed |

||||

|

GBZ-180-6 |

1800 |

6000 |

Adjusted |

≤800 |

240 |

45 |

|

GBZ180-8 |

8000 |

|||||

|

GBZ180-9.5 |

9500 |

|||||

|

GBZ180-10 |

10000 |

|||||

|

GBZ180-12 |

12000 |

|||||

|

GBZ240-4 |

2400 |

4000 |

≤1000 |

400 |

30 |

|

|

GBZ240-5 |

5000 |

|||||

|

GBZ240-5.6 |

5600 |

|||||

|

GBZ240-10 |

10000 |

45 |

||||

Medium Duty and Small Size

|

Model |

Belt Plates |

Feeding Size (mm) |

Capacity |

Power (kW) |

||

|

Belt Width |

Center Distance of sprockets (mm) |

Speed |

||||

|

GBH80-2.2 |

800

|

2200 |

Adjusted |

≤300

|

15-91

|

7.5 |

|

GBH80-3 |

3000 |

4 |

||||

|

GBH80-4 |

4000 |

7.5 |

||||

|

GBH80-5.8 |

5800 |

7.5 |

||||

|

GBH100-1.6 |

1000 |

1600 |

Adjusted |

≤350 |

22-131 |

7.5 |

|

GBH100-3 |

3000 |

|||||

|

GBH100-4 |

4000 |

|||||

Medium Duty and Big Size

|

Model |

Belt Plates |

Feeding Size (mm) |

Capacity |

Power (kW) |

||

|

Belt Width |

Center Distance of sprockets (mm) |

Speed |

||||

|

GBH120-1.8 |

1200 |

1800 |

Adjusted |

≤400

|

35-217

|

7.5 |

|

GBH120-2.2 |

2200 |

|||||

|

GBH120-2.6 |

2600 |

|||||

|

GBH120-3 |

3000 |

|||||

|

GBH120-4 |

4000 |

|||||

|

GBH120-4.5 |

4500 |

|||||

|

GBH120-6 |

6000 |

11 |

||||

DOWNLOAD

DOWNLOAD