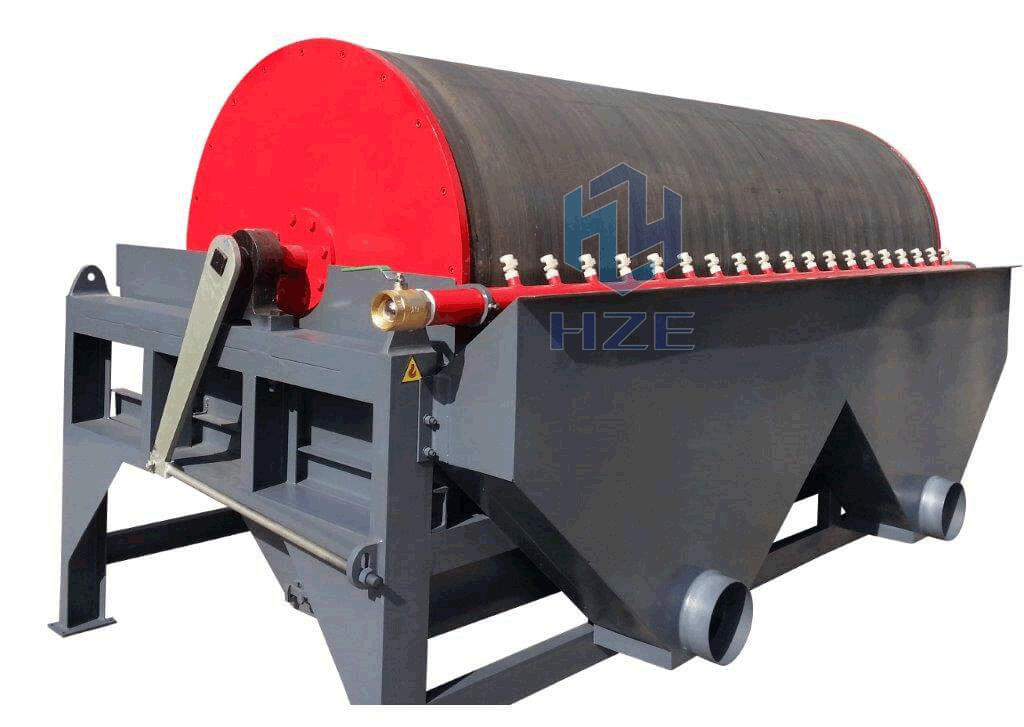

Wet Drum Magnetic Separator

Application

Drum permanent magnetic separators are sorted as following four types:

CTBY separator for pre-concentration: suitable for wet type pre-concentrating magnetite before grinding mills after the ore fine crushing to be less than 10mm.

CTBC separator for roughing: used as rougher after one stage or multi-stage grinding, or the rougher to recover magnetic minerals from the tailings which are separated out nonferrous metals already. The feed particle size should be less than 4mm.

CTBJ separator for cleaning: applied as cleaner to purify the concentrate of roughing after the magnetite ore grinding and classifying. The feed particle size should be less than 2mm.

CTBN separator for thickening: used to thicken and separate sands before they are returned into ball mill or thicken and separate magnetite concentrate before filtration. The feed particle size should be less than 4mm.

Features

Large magnetic envelope angle design which increases the length of the separation area and the number of magnetic inversion, achieve the effective separation of magnetic materials and non (weak) magnetic materials.

Neodymium-iron-boron magnets are used in all magnetic systems to ensure high magnetic field intensity and large depth of action.

The demagnetization rate of magnetic field intensity is less than 5% after 8 years.

The magnetic system is protected by stainless steel plate to ensure that the magnetic block does not fall off.

According to different uses and separation conditions, different types of magnetic separators have different magnetic system design and tank structure.

The tank structure is semi-countercurrent. It can also be made into a downstream tank according to sorting conditions and user requirements.

The shell of the pulley is made of stainless steel and lined with wear-resistant rubber outside, which has a long service life.

The beneficiation indexes of high grade and high recovery can be obtained at the same time.

Technical Parameters

Small Size

|

Model |

Drum Dia. (mm) |

Drum Len. (mm) |

B of Drum Surface (mT) |

Capacity (t/h) |

Power (kw) |

Speed (rpm) |

|

CTB-618 |

600 |

1800 |

Confirmed according to ore properties |

15-30 |

2.2 |

40 |

|

CTB-718 |

750 |

1800 |

20-35 |

3 |

35 |

|

|

CTB-918 |

900 |

1800 |

25-40 |

4 |

28 |

|

|

CTB-1018 |

1050 |

1800 |

45-60 |

5.5 |

22 |

|

|

CTB-1021 |

1050 |

2100 |

50-70 |

5.5 |

22 |

|

|

CTB-1024 |

1050 |

2400 |

60-80 |

5.5 |

22 |

|

|

CTB-1030 |

1050 |

3000 |

80-120 |

7.5 |

22 |

Medium Size

|

Model |

Drum Dia. (mm) |

Drum Len. (mm) |

B of Drum Surface (mT) |

Capacity (t/h) |

Power (kw) |

Speed (rpm) |

|

CTB-1218 |

1200 |

1800 |

Confirmed according to ore properties |

60-75 |

11 |

17 |

|

CTB-1224 |

1200 |

2400 |

80-110 |

11 |

17 |

|

|

CTB-1230 |

1200 |

3000 |

100-140 |

11 |

17 |

|

|

CTB-1236 |

1200 |

3600 |

120-160 |

15 |

17 |

|

|

CTB-1240 |

1200 |

4000 |

130-170 |

15 |

17 |

|

|

CTB-1245 |

1200 |

4500 |

150-200 |

15 |

17 |

Big Size

|

Model |

Drum Dia. (mm) |

Drum Len. (mm) |

B of Drum Surface (mT) |

Capacity (t/h) |

Power (kw) |

Speed (rpm) |

|

CTB-1530 |

1500 |

3000 |

According to ore properties |

100-180 |

11 |

14 |

|

CTB-1540 |

1500 |

4000 |

150-200 |

15 |

14 |

|

|

CTB-1545 |

1500 |

4500 |

180-240 |

18.5 |

14 |

|

|

CTB-1550 |

1500 |

5000 |

210-280 |

18.5 |

14 |

|

|

CTB-1824 |

1800 |

2400 |

100-140 |

15 |

14 |

|

|

CTB-1830 |

1800 |

3000 |

140-190 |

18.5 |

14 |

|

|

CTB-1840 |

1800 |

4000 |

200-260 |

30 |

14 |

|

|

CTB-1850 |

1800 |

5000 |

280-320 |

37 |

14 |

DOWNLOAD

DOWNLOAD