Centrifugal Concentrator

WORKING PRINCIPLE

This concentrator is a kind of high rate gold recovery equipment by gravity. High-speed rotation generates very strong centrifugal force to enhance gravity separation and more effectively recovering GRG (gravity recoverable gold) existing in various minerals.

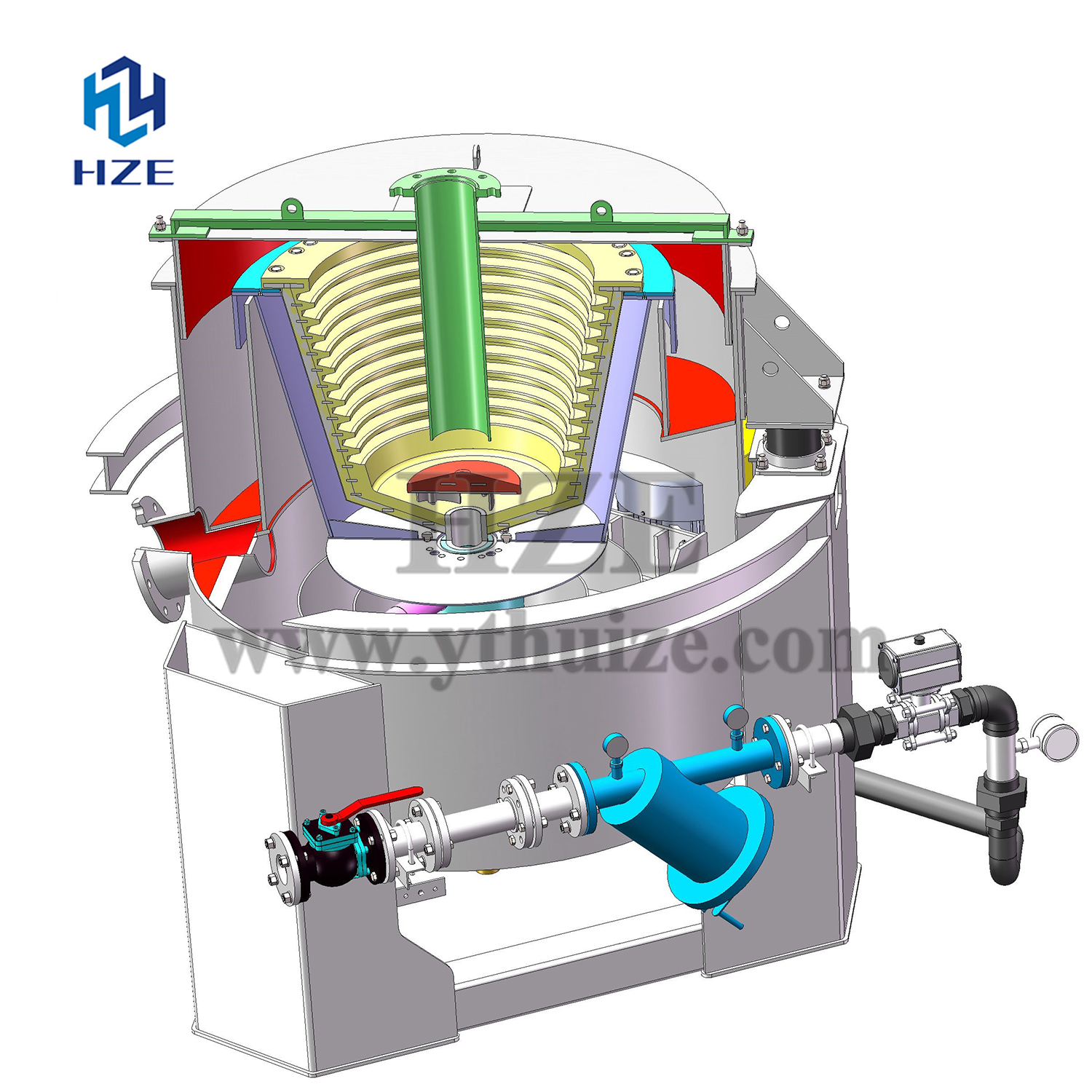

As shown in the figure, the working component of the concentrator is a high-speed rotating cone composed of the wear-resistant concentrating cone and the shell. The space between the concentrating cone and the shell is the water chamber. There are several circular grooves arranged in parallel on the inner side of the concentrating cone, and a series of tangential small water holes are arranged on the side walls of the grooves. During rotation of the cone, the strong centrifugal force amplifies the difference of the mineral particles with different density, thus achieving good separating effect. The slurry is fed into the bottom of the cone. The lighter particles and water move upward along the inner surface of the concentrating cone and overflow out of the top of the cone as tailings. The heavier particles are caught in a series of grooves. The tangential water is injected opposite to the rotation direction of the cone fluidizes the heavy particles entering the groove, forming fluidized concentrating bed to prevent the heavy particles to tightly compact on the side wall of the groove caused by centrifugal force.

This centrifugal concentrator works in a semi-continuous mode. After continuous runing of the concentrating cone for a period of time, the ore feed is closed and the motor is turned off. More water flows out of the fluidized holes to unload the concentrate out of the circular grooves and discharge out of the bottom of the concentrating cone.

ADVANTAGES

Cleanly recover gold by gravity which avoid any chemical for environment friendly; According to the GRG size distribution of the minerals, the rotation speed of the concentrating cone can be adjusted through the frequency converter for the best recovery;

Excellent GRG recovery performance. The recovery rate of 74 μm gold exceeds 98% and the recovery rate of 40 μm gold can reach more than 80%;

The concentration ratio is more than 1000 times, the concentrate yield is small, and the concentrate grade is up to 3000-30000 g/t;

The concentrating cone is lined by highly wear-resistant polyurethane and the slurry discharge launder is lined by wear-resistant rubber lining to obtain an extremely long life and stable continuous operation;

The rotating components undergo strict balance testing, and the concentrator is equipped with good vibration isolators, which can operate smoothly without being mounted by the anchor bolts;

Set process parameters through the human-machine interface, detect each data in real-time during operation, and completely automatically control the operating status of the machine to ensure process goals;

Easy operation and simple maintenance;

Customers can choose the optional components and functions of the concentrator to match the actual needs, and HZE will also provide the customized solutions and products according to the specific requirements of customers.

APPLICATIONS

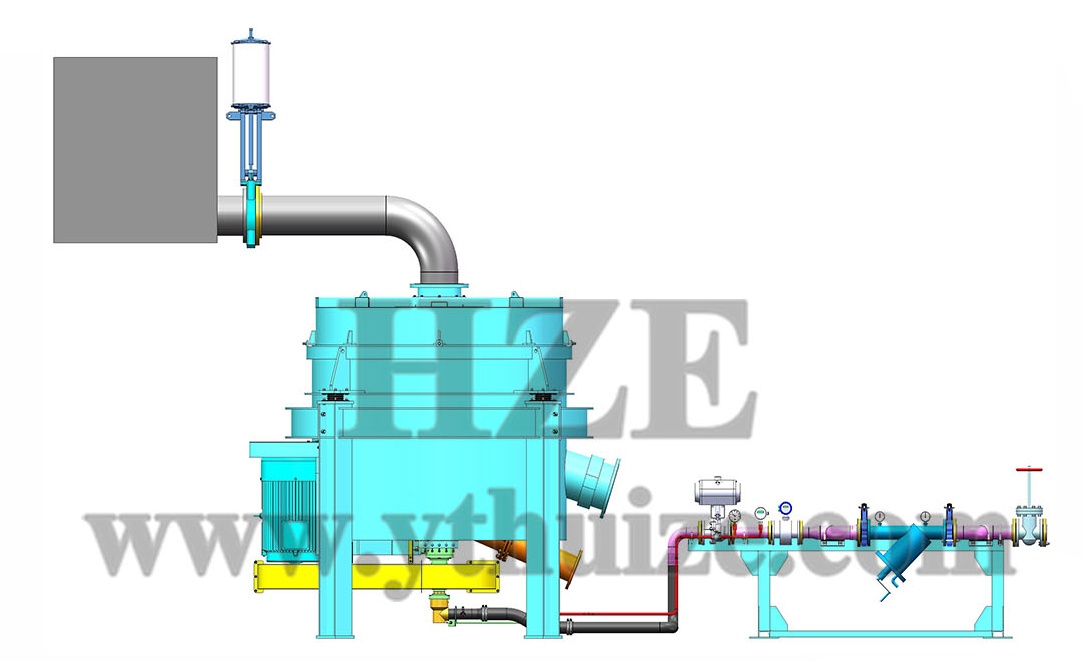

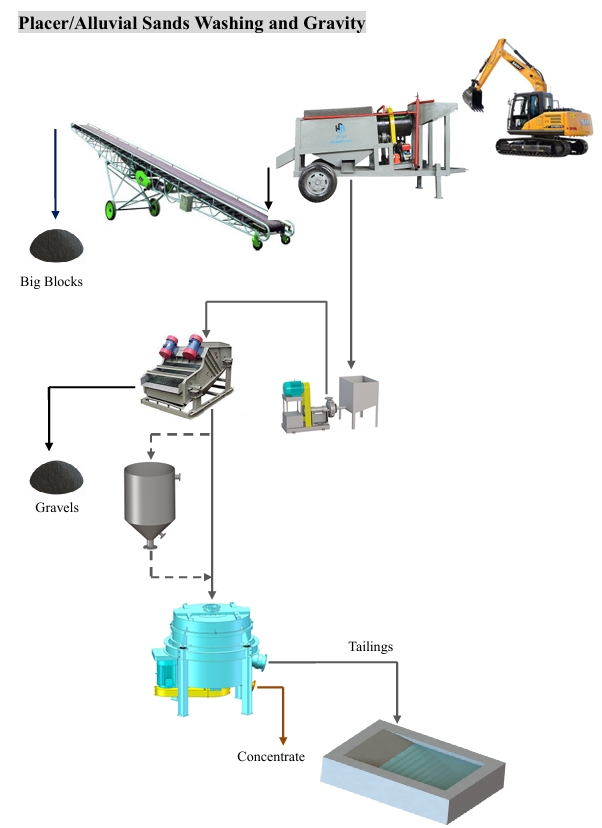

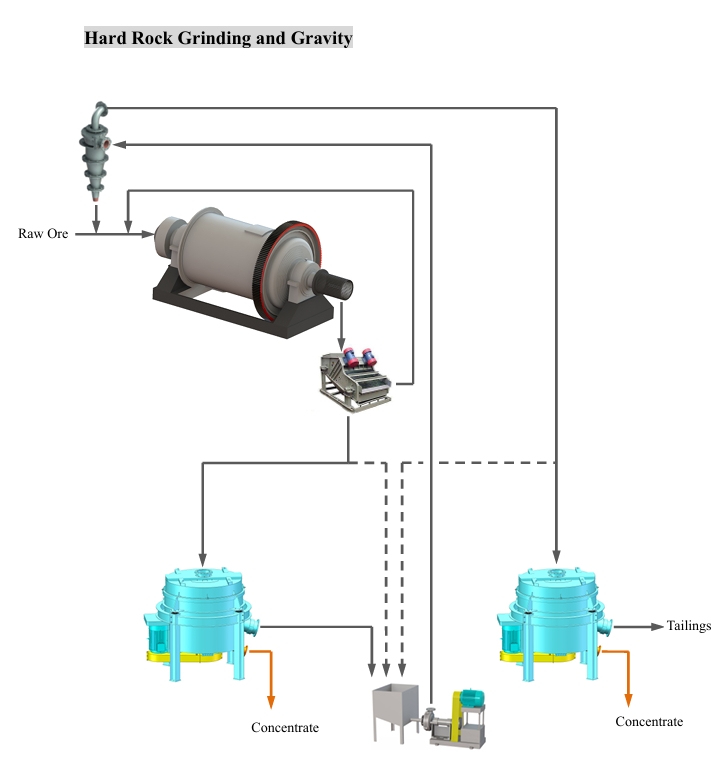

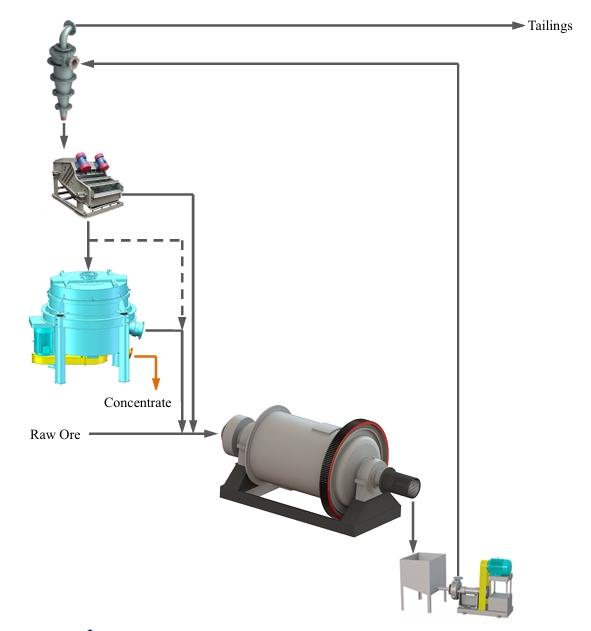

The concentrator can be used for outdoor or indoor operation. It is suitable for recovering GRG from quartz veins, hard rocks, dump tailings, placers or alluvial sands. It can be used alone or in conjunction with grinding systems, flotation systems, leaching systems and washing systems to recover GRG without being affected by environmental and location conditions.

Concentrating Cone Styles

According to the customer's mineral situation, HZE provides two concentrating cone options: C1 and C2. C1 mainly recovers coarse GRG, and C2 is suitable for recovering both moderate and fine GRG.

Specification and ModelSOLUTION EXAMPLE OF GOLD GRAVITY

|

Model |

ALX-12 |

ALX-XD20 |

ALX-XD30 |

ALX-XD40 |

ALX-Q48 |

|

Cone Type |

C2 |

C1, C2 |

C1, C2 |

C1, C2 |

C1, C2 |

|

Solid feeding capacity (t/h) |

5-16 |

10-70 |

50-140 |

75-240 |

100-380 |

|

Feeding particle size (mm) |

Recommended 0-2, Max. 6 |

||||

|

Feeding concentration (%) |

0-75, optimal 50-60 |

||||

|

Max slurry flow (m3/h) |

25 |

100 |

218 |

325 |

540 |

|

60G fluidization water consumption (m3/h) |

4.0-6.1 |

7-14 10-21 |

C1:17-25 C2:25-34 |

C1:26-36 C2:41-55 |

C1:40-53 C2:51-70 |

|

Concentrate weight per batch (kg) |

2.7-4.8 |

8-12 |

C1:21-30 C2:38.5-55 |

C1:29-40 C2:53-73.5 |

C1: 44-52 C2:80.5-95 |

|

Power (kW) |

2.2-5.5 |

5.5-7.5 |

11-22 |

30-45 |

45-75 |

Typical Gold Recovery Solutions

DOWNLOAD

DOWNLOAD