Small Scale Gold Mining Equipment

HZE develop and manufacture series of good reliability and high recovery modular / portable / mobile processing plants and many kinds of small equipment for the small scale and artisanal gold mining owners. With advanced technology, perfect processing, reliable equipment and complete services, HZE provides gold recovery solutions that are conducive to environmental friendly and personal health.

Applications

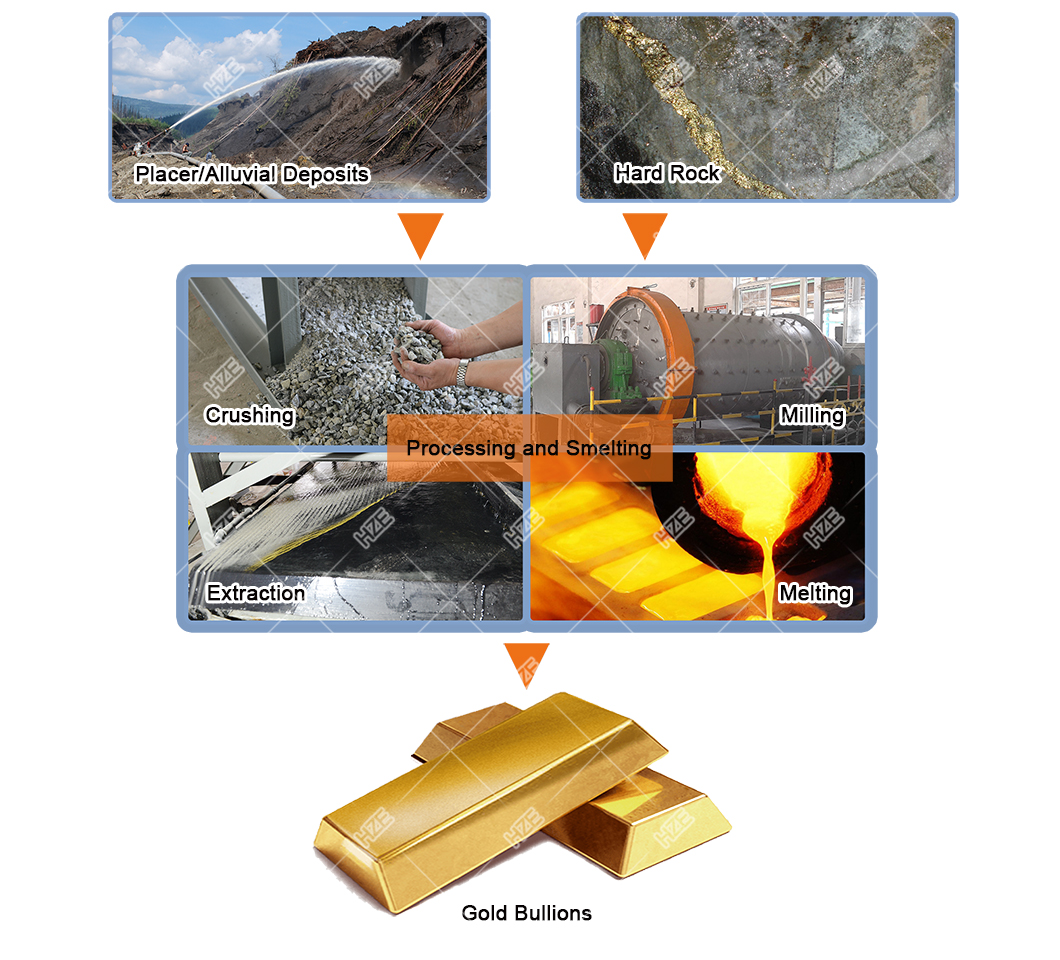

Gold is recovered from placer, alluvial and hard rock deposits by mercury-free methods and gold ingots / bullions are produced.

Products Type

Small Scale Modular Processing Plants

Portable Gold Wash Plant

The coarse and fine particles are completely classified and separated by the trommel. The free gold nuggets and particles existing in undersize slurry are recovered by the sluice box then gold is further enriched by the shaking table to obtain the final concentrate which is melted to cast gold bullions.

Main Equipment: trommel, sluice box, concentration table, pumps.

Capacity: 1t/h, 3t/h, 5t/h, 10t/h, 20t/h, 30t/h, 50t/h

Fee gold recovery: 93%

Mounted type: skid, trailer

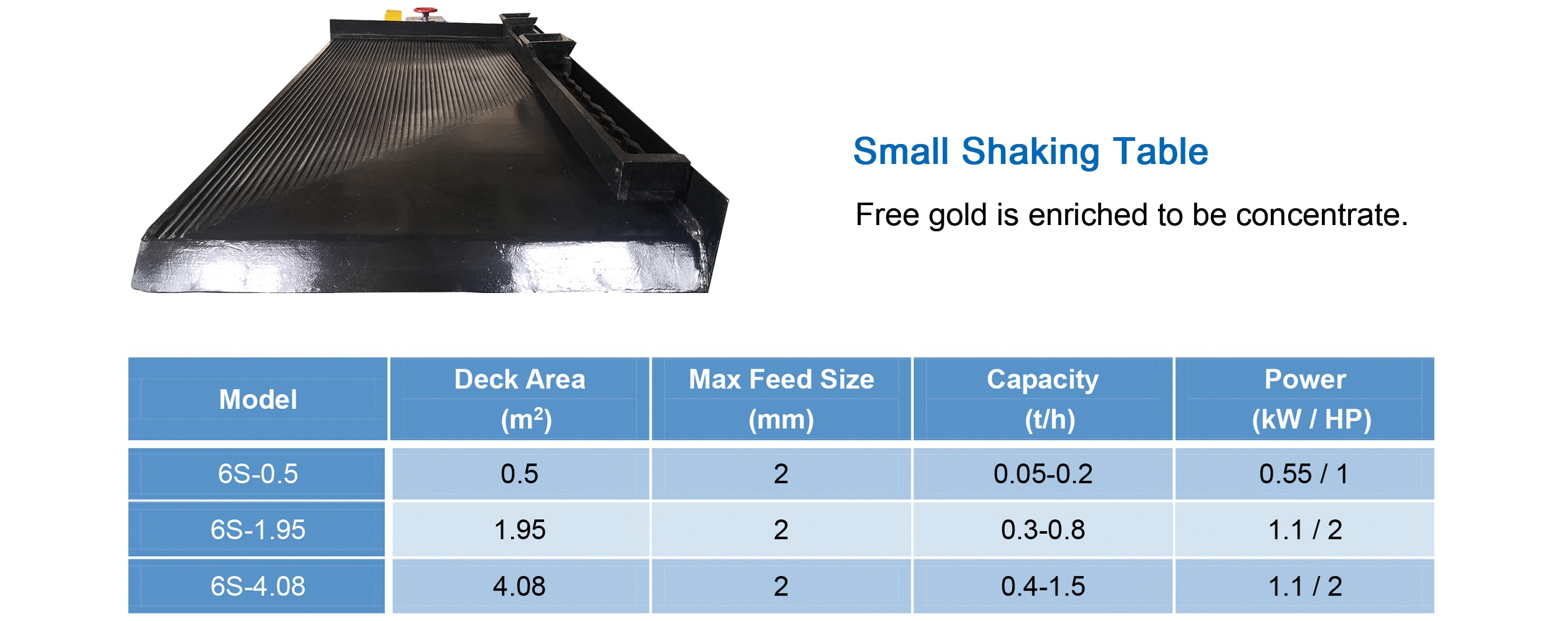

Mini Compact Gold Concentration Plant

The crushed hard rocks or quartz vein ores were comminuted by the supper fine hammer mill to liberate free gold completely then gold is recovered and enriched by the shaking table to get the concentrate which is melted to cast gold bullions.

Main equipment: jaw crusher, hammer mill, shaking table, sluice box, pumps.

Capacity: 500kg/h, 800kg/h, 1000kg/h

Free gold recovery: 97%

Driven type: diesel engine, electric motor

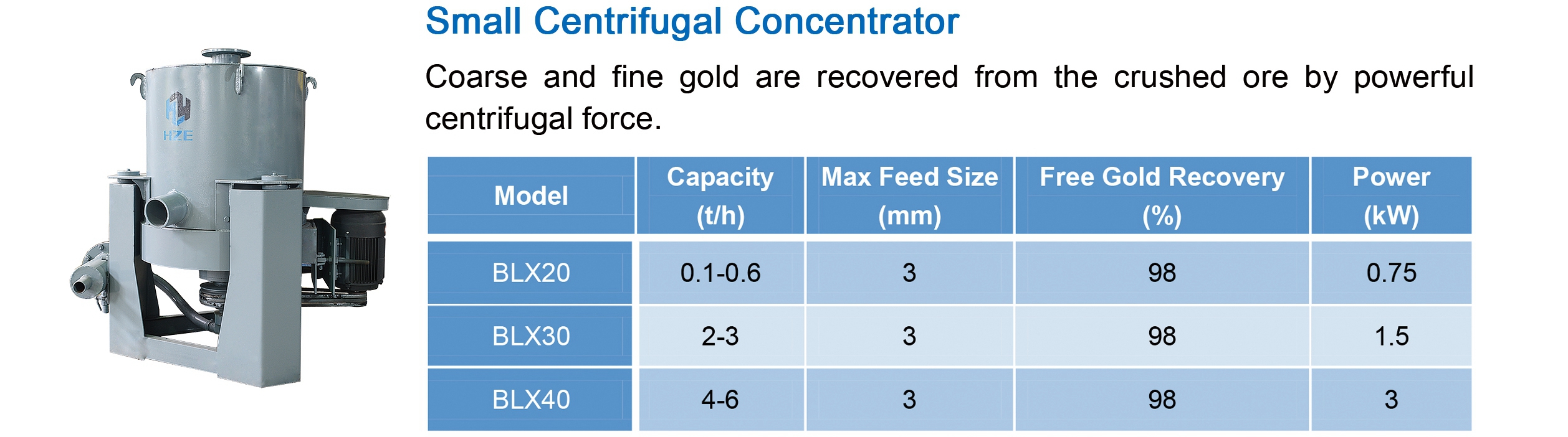

Small Scale Hard Rock Gold Processing Plant

After the hard rocks or quartz vein ores are crushed and milled, the gold is recovered by gravity concentration to obtain the concentrate which is melted to cast gold bullions.

Main equipment: jaw crusher, conveyors, ball mill, centrifugal concentrator, shaking table, sluice box, pumps.

Capacity: 2t/h, 3t/h, 5t/h, 10t/h

Free gold recovery: 98%

Driven type: diesel engine, electric motor

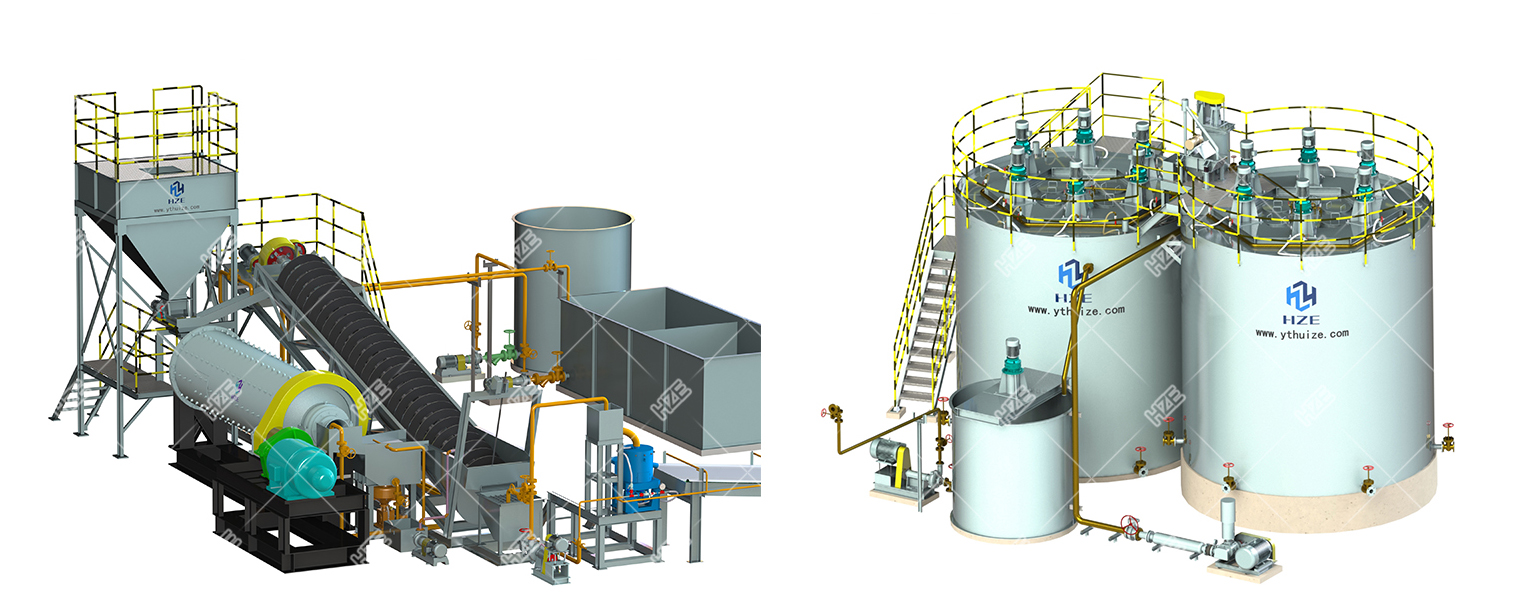

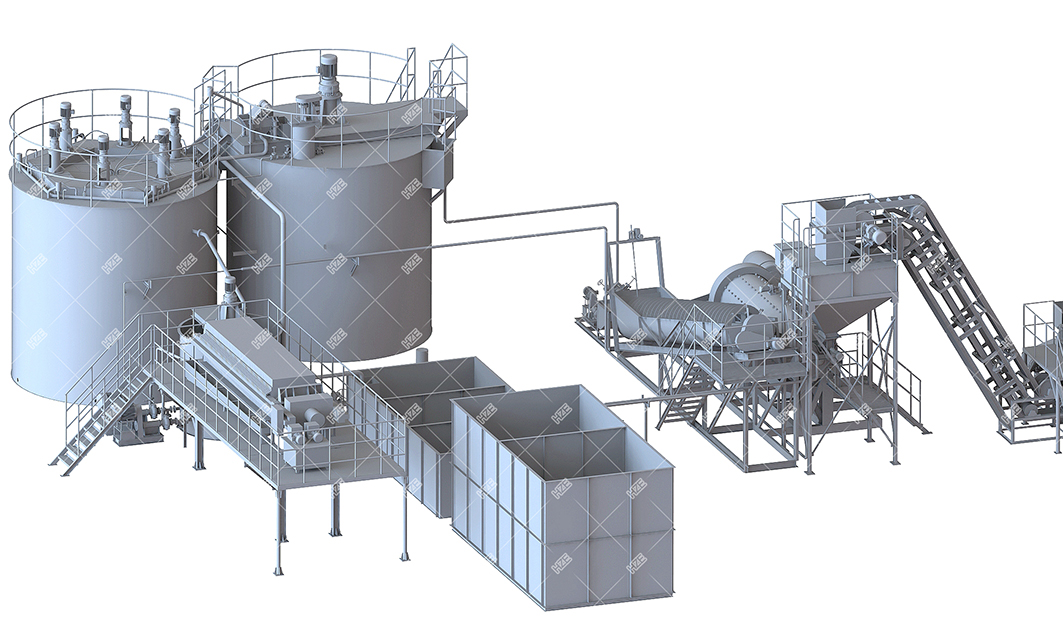

Small Modular Gold Leaching Plant

The Fine gold is extracted by cyanide from the milled ore, then the activated carbon adsorbs gold, finally the elution and electrowinning unit produces gold sludge which will be melted to cast gold bullions.

Main equipment: jaw crusher, conveyors, ball mill, integrated tank, elution and electrowinning unit, pumps.

Capacity: , 1t/h, 2t/h, 3t/h, 5t/h

Gold recovery: >94%

Driven type: diesel engine, electric motor

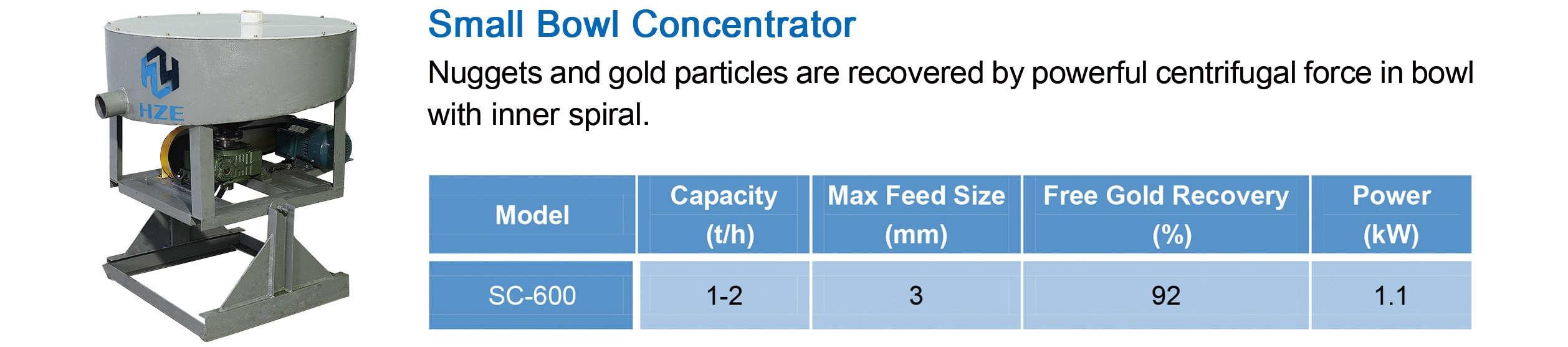

Small Machines

Small Melting Equipment Kit

Concentrate-borax and Flame Oven Kit

The concentrate is mixed with borax after iron removal then it is smelted in the flame oven to cast bullions.

Amalgamation Retort and Smelting Kit

The concentrate is further ground and mixed with mercury after iron removal, and the amalgam is distilled in a closed retort then it is smelted by the propane torch to get the ingot.

Concentrate-borax and Medium Frequency Induction Furnace Kit

The concentrate is mixed with borax after iron removal then it is smelted in the medium frequency induction smelting furnace to cast bullions.

Solutions

HZE fully understands the details of each client's gold deposit and fully communicates with the client to customize the most suitable scheme. HZE provides one-stop service including process design, equipment manufacturing, installation, commissioning and training, so as to help the clients to produce gold with advanced technology and reliable equipment under the condition of saving investment, realize the goals of environmental friendly, energy saving, consumption reduction and high profit.

Small modular plants and equipment are mobile for easy moving from one mining area to another site.

Small modular plants and equipment are lightweight and compact in size. The equipment can be driven by motor or diesel engine, which is convenient to use in remote areas.

Free of civil engineering investment or little investment in civil engineering, quick site installation, low investment costs and fast recovery of funds.

Compared with the mercury amalgamation, the gold recovery rate is increased by more than 10%, and it is conducive to environment and human health.

With good reliability and simple operation, small scale artisanal miners are easy to become experts in gold mining and processing industries.

The small plants can be used as pilot plants for large-scale projects or as a processing plants during prospecting.

DOWNLOAD

DOWNLOAD