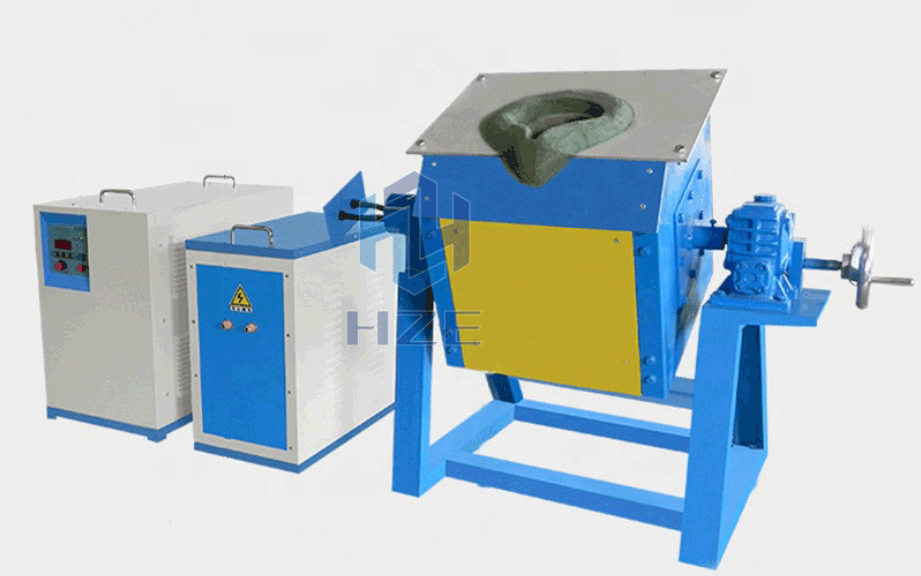

Medium Frequency Induction Melting Furnace

Working Principle

Medium frequency induction melting furnace is a power supply device which converts 50 HZ AC power frequency into medium frequency (300 HZ or more to 1000 HZ). It converts three-phase AC power frequency into direct current after rectification, and then converts direct current into adjustable medium frequency current. Intermediate frequency alternating current passes through the induction coil, generating high density magnetic force line, and cuts the metal materials placed in the induction coil, which generates large eddy current in metal materials. It uses electromagnetic induction to heat metals.

Composition

Medium frequency induction melting furnace includes medium frequency power supply, compensation capacitor box and melting furnace.

Characteristics

Medium frequency melting has a good electromagnetic stirring effect, which is beneficial to the uniformity of temperature and structure of melted metal. It helps to float the impurities onto liquid metal and reduce impurities in the bullion.

Wide frequency range, which is from 1 KHZ to 20 KHZ.

Electric energy saving to at least 20%.

The equipment is small in size and light in weight. The melting capacity ranges from several kilograms to several hundred kilograms.

At normal atmospheric temperature, the time of its bath melting is 50 - 60 minutes. When the furnace body keeps high temperature, the time is 20-30 minutes.

Application Scope

Used for melting steel, stainless steel, copper, aluminum, gold, silver and other metals.

Technical Parameter

|

Model |

Power (kW) |

Melting Capacity Per Batch (Kg) |

|

TXZ-15 |

15 |

10 |

|

TXZ-25 |

25 |

20 |

|

TXZ-35 |

35 |

40 |

|

TXZ-45 |

45 |

70 |

|

TXZ-70 |

70 |

100 |

|

TXZ-90 |

90 |

120 |

|

TXZ-110 |

110 |

150 |

|

TXZ-160 |

160 |

200 |

DOWNLOAD

DOWNLOAD