High Efficiency Elution and Electrowinning Plant

Brief Description of Elution-Electrowinning

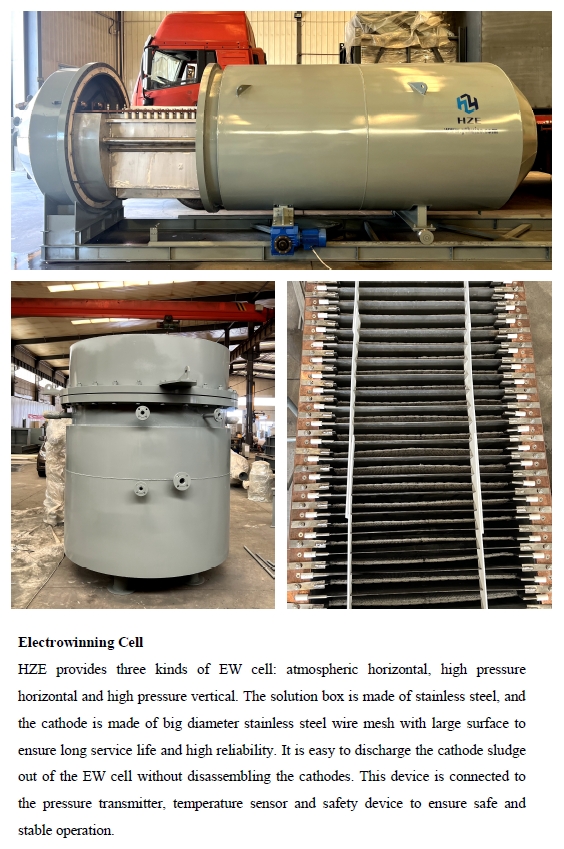

The eluant containing desorption chemicals flows from bottom to top through the stationary bed of loaded carbon in the elution column at the set temperature. The gold-cyanide complex ions adsorbed on the surface of the carbon are eluted into the solution and become eluate (pregnant solution). The eluate is overflowed from the top of the elution column through the screen and flows into the electrowinning cell which deposits the gold as cathode sludge on a series of cathodes.

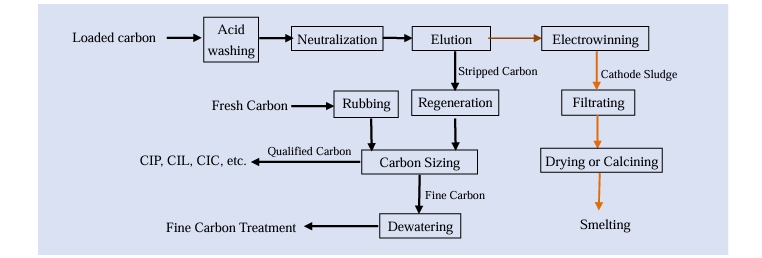

Typical Block PFD

Atmospheric Zadra Stripping Unit

The eluant strips the gold from the loaded carbon below the boiling point. The system operates at a proper flow rate for longer time. The advantages are less safety requirements and low capital costs.

Pressurized Zadra Stripping Unit

The eluant is heated to 140°C to rapidly desorb gold off the loaded carbon. The eluate proceeds to electrowinning after heat exchange, cooling, and pressure reduction. The system generally completes the cycle within 8-12 hours.

Integrated Pressure Stripping Unit

This unit is abbreviated as IPS. All equipment and pipelines of the elution - electrowinning unit operates are connected to form a closed system. The working temperature of the eluant is 150°C. The gold-cyanide complex becomes instable in the pressurized electrowinning cell which increases the electrowinning efficiency. The rapid stripping rate is obtained when the solution is returned back to the elution column because of the better desorption kinetics. The system completes the cycle within 6-10 hours. It has the most thermal efficient and the least energy consumption.

Specifications

|

Items |

Atmospheric Zadra Stripping Unit |

Pressure Zadra Stripping Unit |

Integrated Pressure Stripping Unit |

|

Working temperature (℃) |

<100 |

Elution: 140 Electrowinning: <90 |

150 |

|

Working pressure (Mpa) |

Atmos |

Elution: 0.37 EW: Atmos |

0.5 |

|

Cycle time (hours) |

48-72 |

8-12 |

6-10 |

|

Eluant flowrate (BV/hour) |

1.5-2.5 |

2-3 |

2-4 |

|

Carbon loading per batch (ton) |

0.1-10 |

0.1-30 |

0.1-30 |

|

EW voltage (V) |

2.5-6 2.5-4 |

2.5-6 2.5-4 |

2.5-6 2.5-4 |

|

Grade of elution carbon gold (g/t) |

<110 |

<100 |

<100 |

|

Electrolysis rate (%) |

>99 |

>99.2 |

>99.2 |

|

Control mode |

Manual / automatic |

||

Features

DOWNLOAD

DOWNLOAD