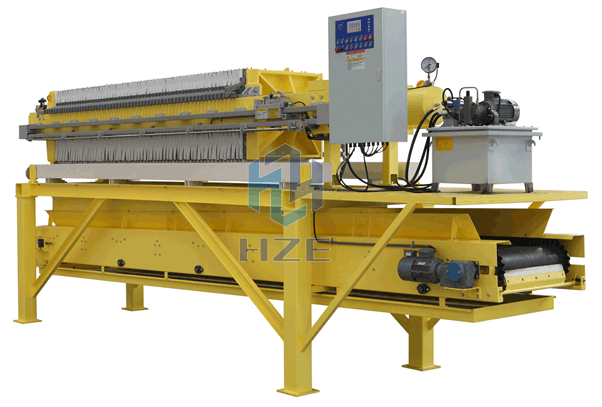

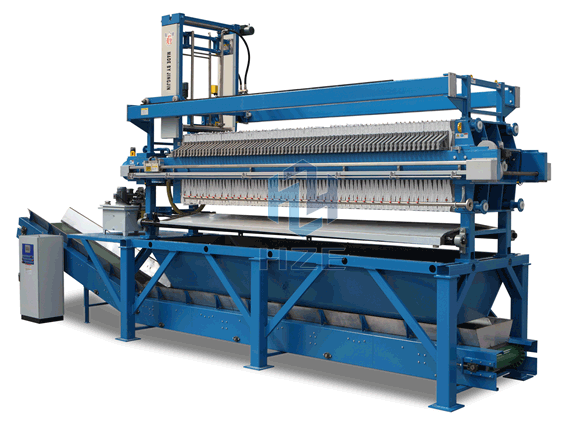

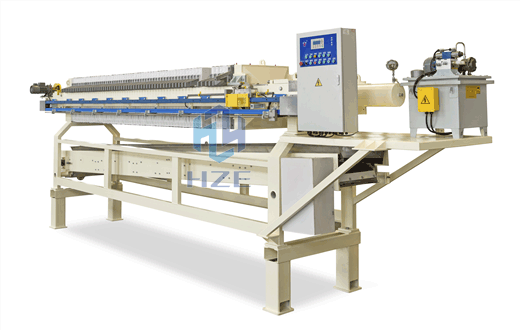

Automatic Chamber Filter Press

Working Principle

A series of filtration plates are arranged to form many filtrating chambers (each filter plate is concave at both surfaces, and each two filter plates are combined into a case-shaped filtrating chamber). Both surfaces of every filtration plate have many protuberances and bumps to support the filtration cloth. There are through holes in the center and corner of the filtration plates to form complete channels After assembly. Suspension, wash water and extract filtrate can flow into the channels and flow out. Each side of every filtration plate is supported by a handle on the frame, and all filtration plates are pressed tightly by the hydraulic system. The filtration cloth between the filter plates acts as the seals.

The slurry pump pressurizes the slurry and feeds it into each filtrating chamber. The liquid flows through the filter cloth then flows along the filter plate groove to the outlet channel below for collecting to discharge. Solid is retained in the chamber surrounded by filter cloth to produce filtrated residue. It is the process to separate solid and liquid. The filter residue accumulates more and more so the residue fills the chamber to get the filtration cake. The filtration plates are opened to discharge the cake after the filtration cycle is finished. Then the filter cloth is cleaned and all filtration plates are pressed tightly once again for next filtration cycle.

Features

High operation efficiency, good performance, filtration plate long life, intelligent automatic control, convenience to replace filtration cloth.

Applications

It is widely used in mining and processing, chemicals, metallurgy and waste water treatment in various industries.

Technical Parameters

Technical Parameters

Small Size

|

Model |

Filtration Area (m2) |

Filtrating Chamber Quantity |

Plate Size L×H (mm) |

Filtrated Cake Thickness (mm) |

Chamber Volume (m³) |

Power (kW) |

|

XMZ20/800U |

20 |

20 |

800×800 |

30 |

0.287 |

2.2 |

|

XMZ30/800U |

30 |

30 |

0.453 |

|||

|

XMZ40/800U |

40 |

40 |

0.605 |

|||

|

XMZ50/800U |

50 |

50 |

0.756 |

|||

|

XMZ60/800U |

60 |

60 |

0.907 |

|||

|

XMZ70/800U |

70 |

70 |

1.059 |

|||

|

XMZ80/800U |

80 |

80 |

1.21 |

|||

|

XMZ40/900U |

40 |

32 |

900×900 |

30 |

0.59 |

2.2 |

|

XMZ50/900U |

50 |

40 |

0.75 |

|||

|

XMZ60/900U |

60 |

47 |

0.88 |

|||

|

XMZ70/900U |

70 |

63 |

1.19 |

|||

|

XMZ60/1000U |

60 |

38 |

1000×1000 |

30

|

0.9 |

2.2 |

|

XMZ80/1000U |

80 |

50 |

1.19 |

|||

|

XMZ100/1000U |

100 |

62 |

1.48 |

|||

|

XMZ120/1000U |

120 |

75 |

1.8 |

Medium Size

|

Model |

Filtration Area (m2) |

Filtrating Chamber Quantity |

Plate Size L×H (mm) |

Filtrated Cake Thickness (mm) |

Chamber Volume (m³) |

Power (kW) |

|

XMZ125/1250U |

120 |

46 |

1250×1250 |

32 |

1.9 |

4 |

|

XMZ150/1250U |

150 |

58 |

2.41 |

|||

|

XMZ180/1250U |

180 |

69 |

2.88 |

|||

|

XMZ200/1250U |

200 |

77 |

3.22 |

|||

|

XMZ220/1250U |

220 |

84 |

3.51 |

|||

|

XMZ250/1250U |

250 |

95 |

3.98 |

|||

|

XMZ300/1500U |

300 |

77 |

1500×1500 |

32 |

4.76 |

5.5 |

|

XMZ320/1500U |

320 |

83 |

5.14 |

|||

|

XMZ340/1500U |

340 |

88 |

5.45 |

|||

|

XMZ350/1500U |

350 |

90 |

5.58 |

|||

|

XMZ380/1500U |

380 |

98 |

6.08 |

|||

|

XMZ400/1500U |

400 |

103 |

6.39 |

|||

|

XMZ450/1500U |

450 |

116 |

7.21 |

|||

|

XMZ500/1500U |

500 |

128 |

7.96 |

Big Size

|

Model |

Filtration Area (m2) |

Filtrating Chamber Quantity |

Plate Size L×H (mm) |

Filtrated Cake Thickness (mm) |

Chamber Volume (m³) |

Power (kW) |

|

XMZ560/2000U |

560 |

80 |

2000×2000 |

40 |

11.16 |

11 |

|

XMZ600/2000U |

600 |

86 |

12.01 |

|||

|

XMZ630/2000U |

630 |

90 |

12.58 |

|||

|

XMZ670/2000U |

670 |

96 |

13.43 |

|||

|

XMZ710/2000U |

710 |

101 |

14.13 |

|||

|

XMZ750/2000U |

750 |

107 |

14.98 |

|||

|

XMZ800/2000U |

800 |

114 |

15.97 |

|||

|

XMZ850/2000U |

850 |

121 |

16.96 |

|||

|

XMZ900/2000U |

900 |

128 |

17.95 |

|||

|

XMZ950/2000U |

950 |

135 |

18.94 |

|||

|

XMZ1000/2000U |

1000 |

142 |

19.92 |

|||

|

XMZ1060/2000U |

1060 |

151 |

21.2 |

|||

|

XMZ1120/2000U |

1120 |

159 |

22.33 |

|||

|

XMZ1180/2000U |

1180 |

168 |

23.61 |

DOWNLOAD

DOWNLOAD