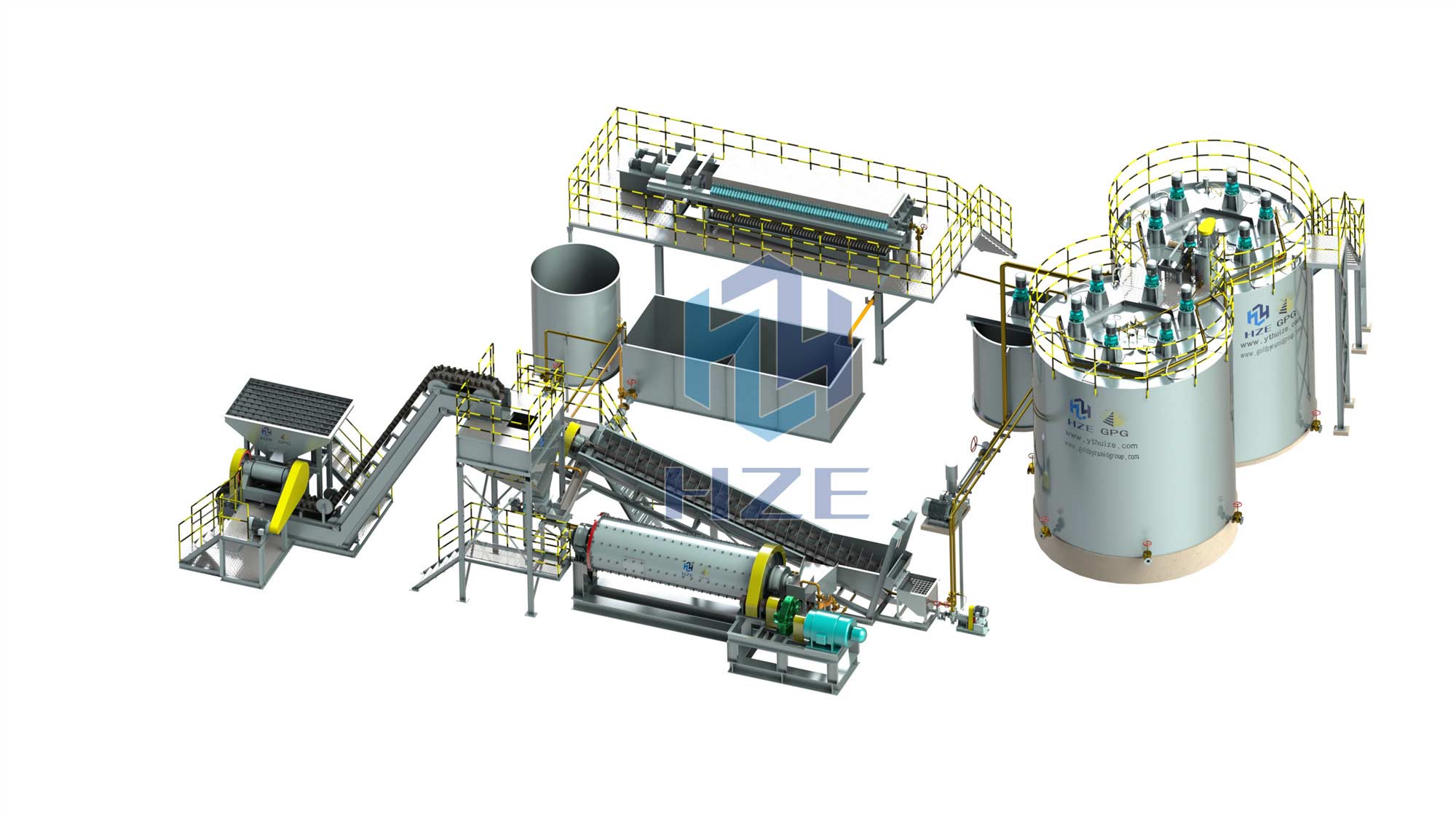

Small Scale Modular Gold CIP/ CIL Plant

APPLICATION

The modular CIP/CIL plant recovers free gold from the sulfide ores, oxidized ores, alluvial or tailings.

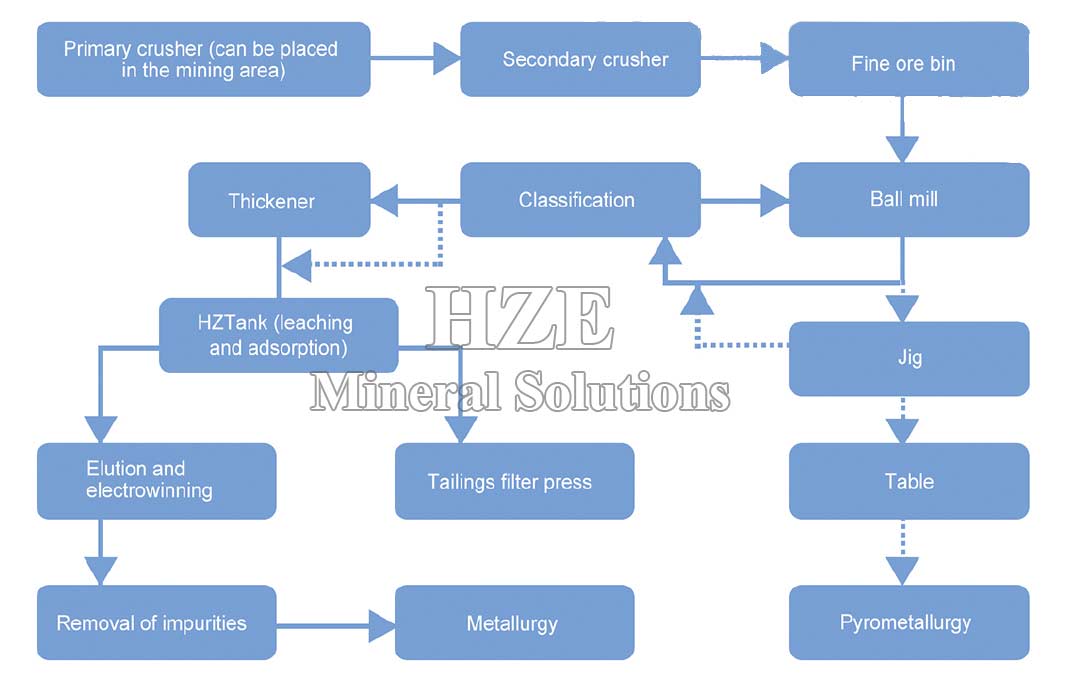

MAIN FLOWCHART

functional modules

For the situations of raw materials and the customer’s requirements, it is free to select the comminution module, grinding and classification unit, gravity concentration module, thickening module before leaching, pretreatment module, leaching and adsorption unit, air supply module, water supply module, power supply module, tailings dewatering module and elution & electrowinning system to form a complete plant which recovers gold as much as possible.

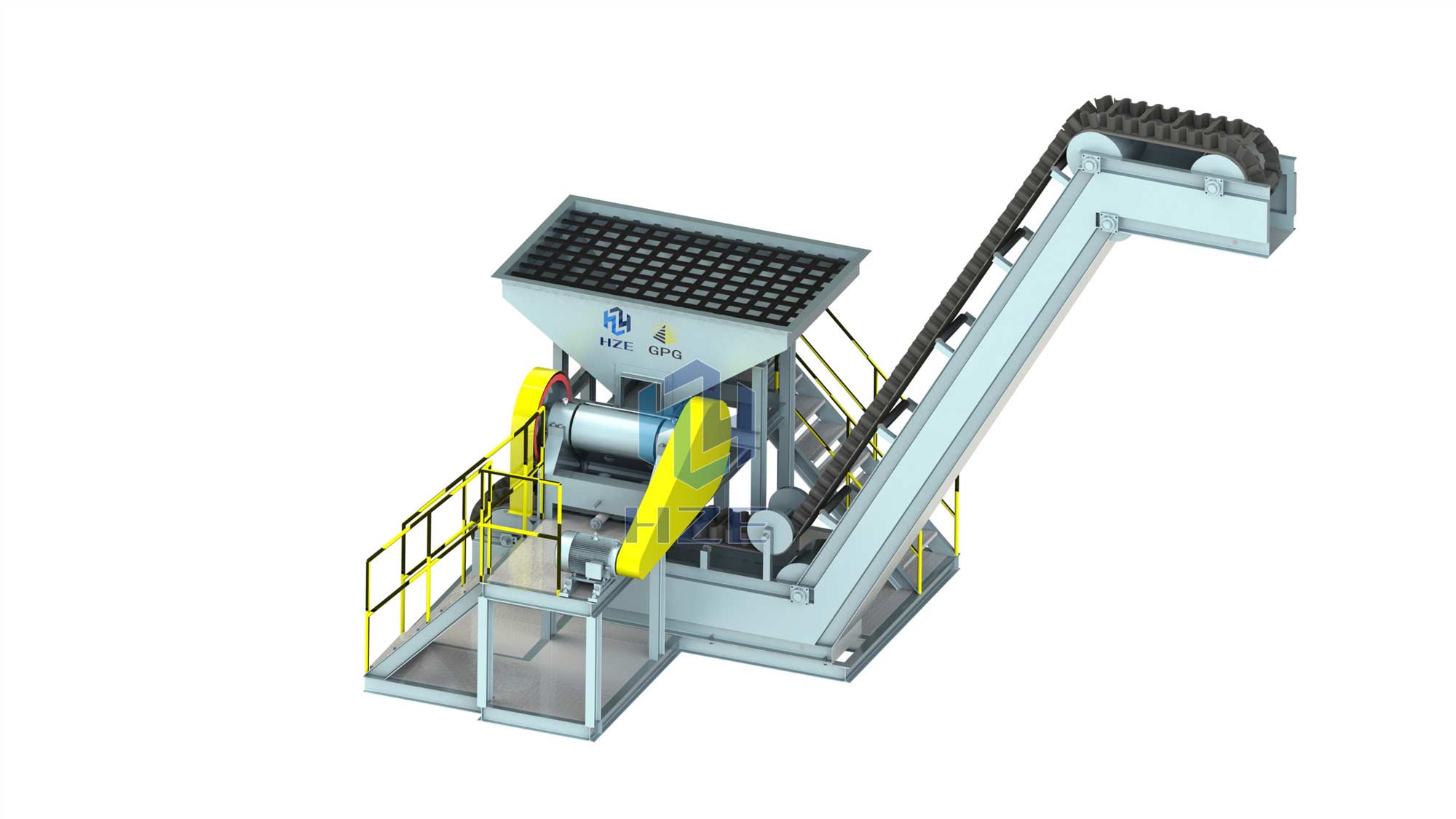

Crushing module

The rocks are crushed to the qualified particle size for grinding. The module is composed of hoppers, crushers, belt conveyors, feeders and so on.

The ores are usually crushed in two stages. According to the actual situation of the site, the primary crusher can be mounted in the mining area or the processing plant. The crusher is usually driven by a diesel engine if it is located in the mining area.

Grinding and classification unit

The closed-circuit grinding and classification system consisting of the ball mill and spiral classifier can liberate ore into the suitable particles for recovering gold. The unit can be adjusted to a closed-circuit system consisting of the ball mill, slurry pump and hydrocyclone if the customer demands.

The grinding and classification unit is amounted in the whole steel frame.

Water supply module

It is composed of the water tanks, water pumps and water supply pipeline. The optimized water balance is achieved by the controlled the utilization rate of water.

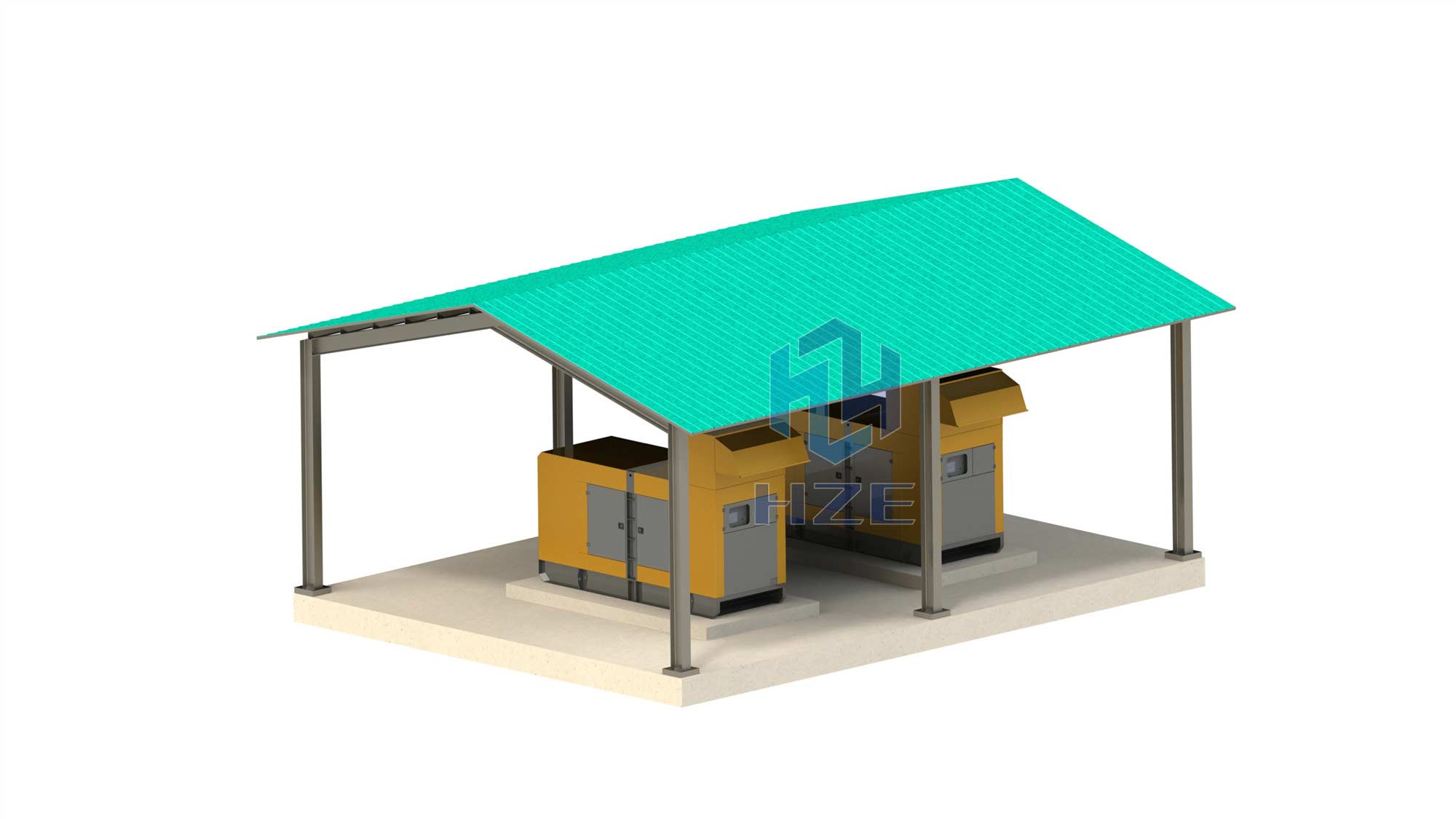

Power supply module

It is composed of the diesel generators, distribution devices and the starting panels and so on. The module is suitable for the areas with inconvenient traffic and shortage of the power grid.

Note:

It is recommended to add gravity concentration module to recover coarse grain gold if a certain amount of free gold exists in the raw materials. Usually the jig is a into the grinding and classification circuit to recover the coarse gold particles then the rough concentrate of the jig is sent to the shaker for cleaning.

The thickening module before leaching should be used to increase the slurry density to meet the needs of leaching and adsorption if the slurry density discharged from grinding and classification unit is low.

The pretreatment module is used before leaching to eliminate the influence of harmful substances on leaching and improve the recovery rate if the raw materials contain some harmful composition such as oxidized copper o ore, arsenic and micro-fine carbon.

It is strongly recommended that tailings dewatering module is used to reduce the consumption of water and cyanide and is conducive to environmental protection.

The customer freely select the high efficiency elution and electrowinning system. The carbon can be burned if the investment is hoped to reduce or the operation life of the plant is short.

Specific Modules

Thickening Module before Leaching

If the grinding and classification unit is composed of the ball mill and hydrocyclone, the density of slurry after classification is low. It is necessary to increase the density to 40-45% before leaching.

The thickening module consists of the thickener and a flocculant feeding device.

The purpose of flocculant feeding is to reduce the settling area of the thickener and shorten settling time, so as to reduce equipment investment and improve the settling efficiency.

Leaching and Adsorption Module

The leaching and adsorption operations are executed by the integrated HZTank with proprietary technology. Depending on the ore conditions, the number of HZtank can be defined freely to combine the production line to achieve the processing of CIP or CIL as well as the required duration of leaching and adsorption.

HZTank is divided into six independent leaching chambers from a whole cylinder. Each leaching chamber has completely independent agitator and air supply device. The slurry in the previous chamber gravitates to the next chamber to form the continuous processing with easy management and operation.

The unique air supply device of HZtank distributes the bubbles evenly in the tank, so that oxygen can fully participate in chemical reaction which greatly improves the oxygen utilization rate and reduces the air supply. The air fed in the tank agitates slurry so the input power of the agitator can be reduced to achieve the purpose of energy saving.

If HZtank is used in the adsorption stage, an interstage screen is installed between two adjacent leaching chambers to ensure that the activated carbon is kept in each chamber. The activated carbon in every chamber is transferred countercurrent by the air lifters to keep the integrity of the activated carbon particles for reducing the loss of gold.

Air Supply Module

The module consists of the air blower and the pipeline system. It supplies oxygen for the leaching chemical reaction and energy of motion for transferring the loaded carbon.

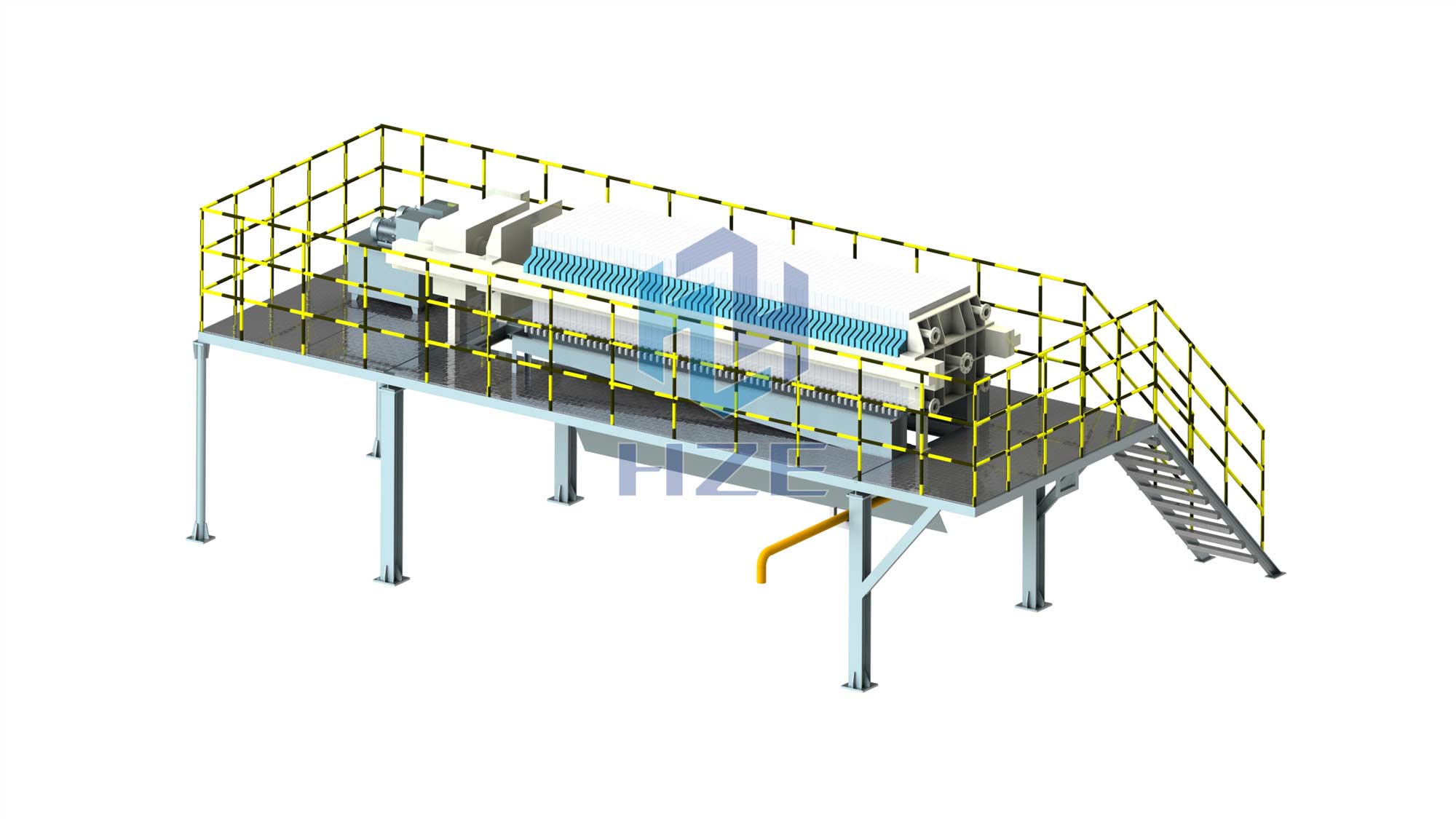

Tailings Dewatering

The tailings of leaching are transported by slurry pump to the automatic filter press for dewatering, and the filter cake is transported to the outside of the plant for storage. The water can be returned to the plant for maximum reuse, and the remaining reagents in the solution can be returned to the plant for fully use, which is not only conductive to the environmental protection, but also reduces the water resources and reagents consumption.

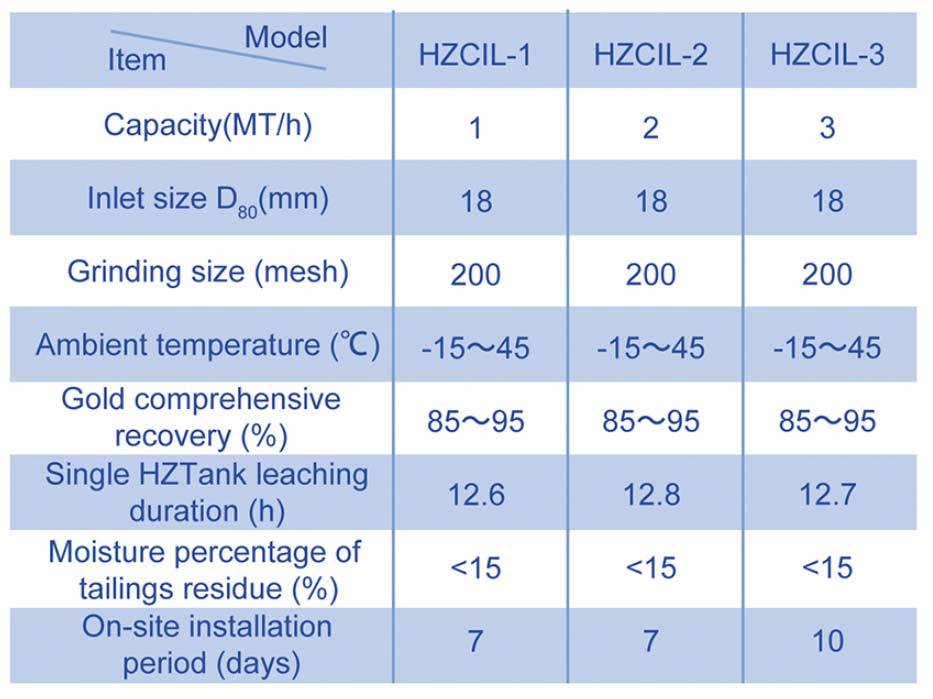

Specifications