Artisanal and Small Scale Gold Mining Processing Plant

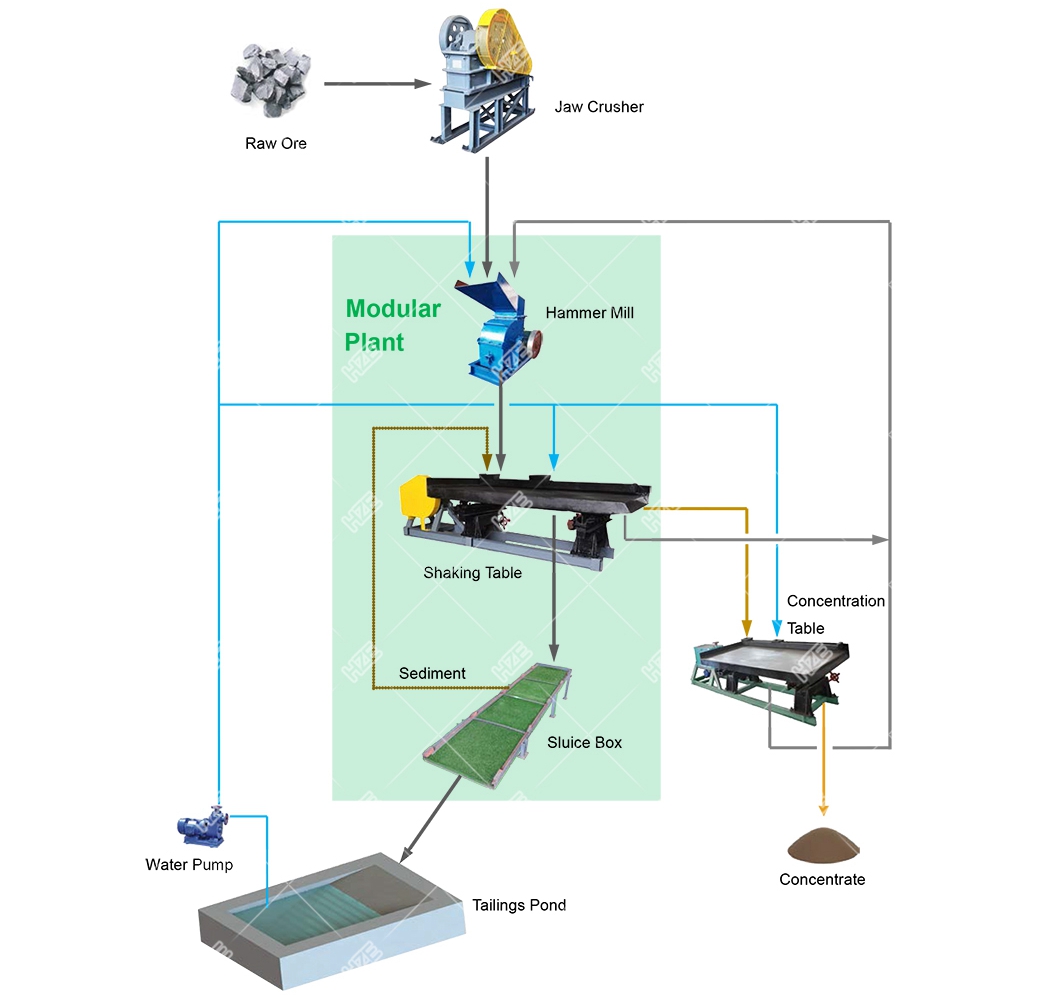

Processing Flowchart

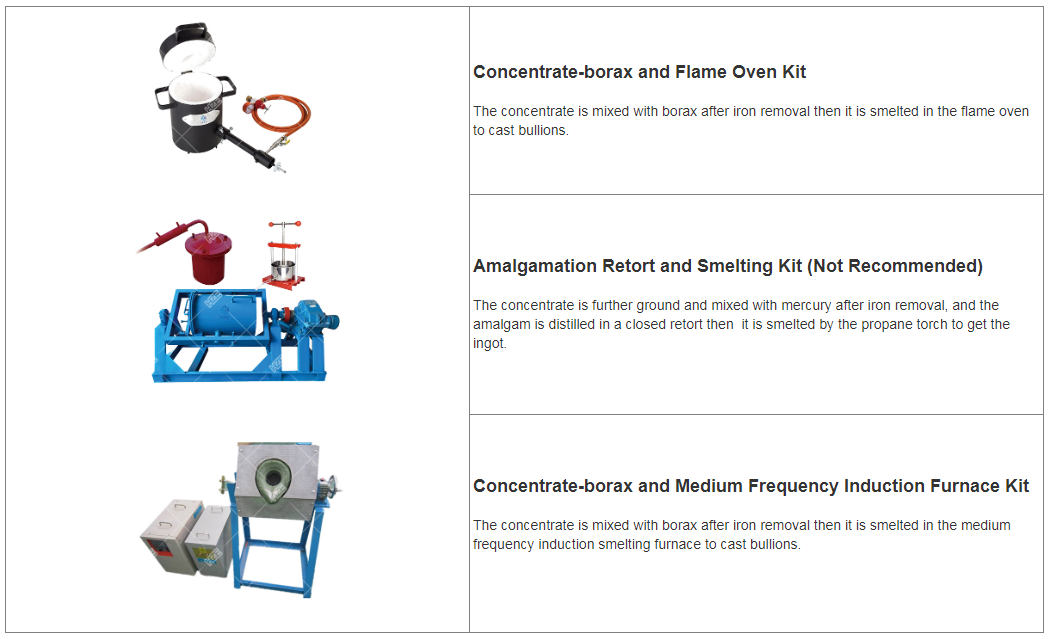

The raw ore is first crushed by the jaw crusher, then it is fully crushed by the hammer mill to liberate free gold completely. gravity separation processing obtains the concentrate is further smelted and casted to get the bullion.

The processing plant adopts the recovery processes without mercury or other chemicals so it is good for environmental friendly and health protection.

Advantages

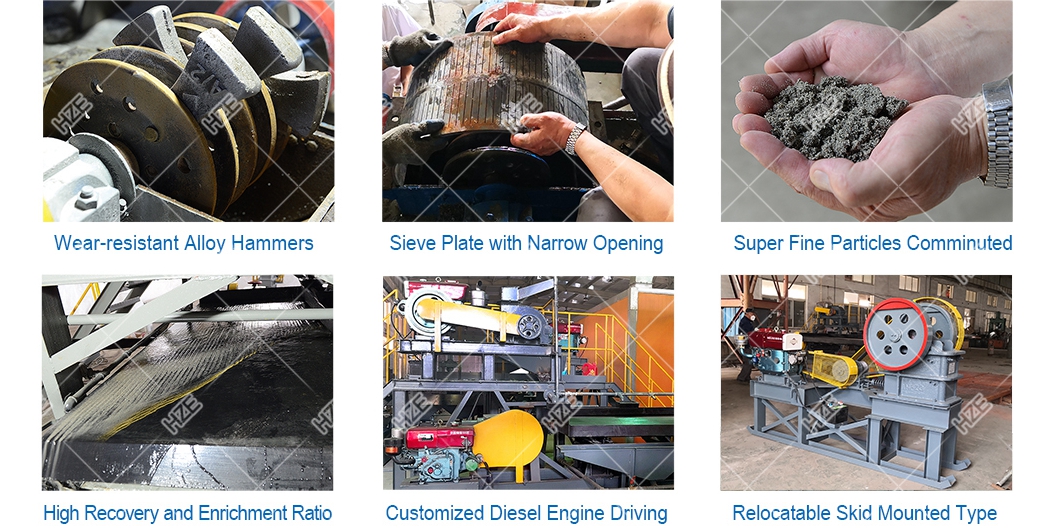

1. The skid mounted modular structure of the plant is convenient to be loaded into the containers. All of equipment, pipelines and wiring of the plant are connected already before ex-work which is easy for transportation and quick install on site.

2. The opening slots of the sieve plate of the hammer mill are made by the laser cutter, and the different slot sizes can be selected according to the actual needs. The slot precision is high. P80 is 60 mesh (0.246 mm) when the maximum product particle size is 0.8mm which is similar as that of ball mill, so that the free gold can be fully liberated and the plant recovery rate of recoverable gold for gravity concentration is up to more than 95%.

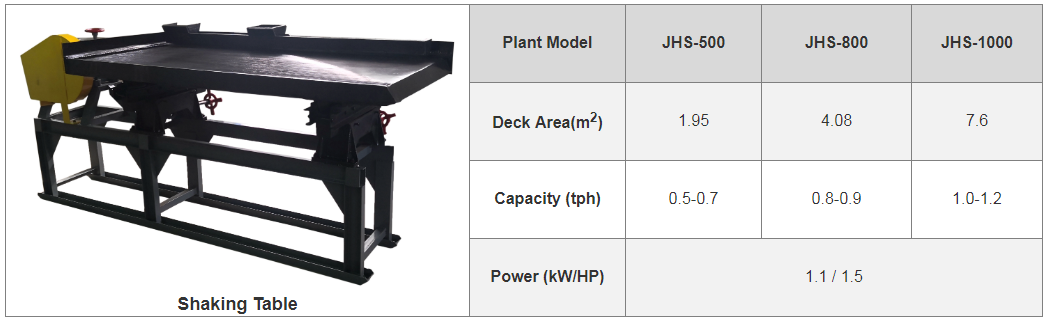

3. The optimized deck and driving device of the shaking table can greatly improve the enrichment ratio and recovery.

4. The plant has good adaptability without special requirements to installation site, temperature and environment, so it can be widely and flexibly used in remote mining areas.

5. The small weight and portable structure of the whole plant makes it easy to move from one mining area to another and finish installation and commissioning in 2 hours.

6. The driving mode can be freely selected as the electric motors or diesel engines, or customized according to customer needs.

7. Low capital cost makes it easy for artisanal and small scale mine owners to procure the plants to replace the existing mercury amalgamation to recover gold and cause environmental friendly and good health.

8. The material of the wearing parts is high wear-resistant alloy steel for long life. It is easy to maintain and operate.

9. High efficiency, small footprint and energy saving.

Applications

The plant is suitable for artisanal and small-scale mine owners to recover granular gold from quartz vein ore, hard rock ore, alluvial deposit, placer deposit and other materials.

The plant can be fixed in one place for operation, or often moved to different mining areas.

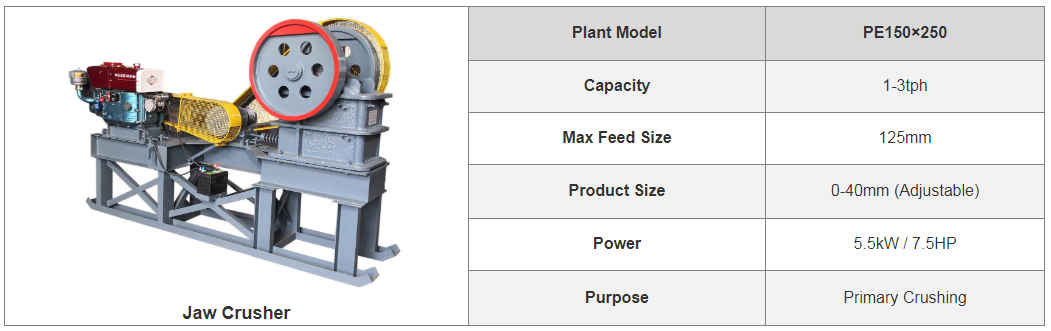

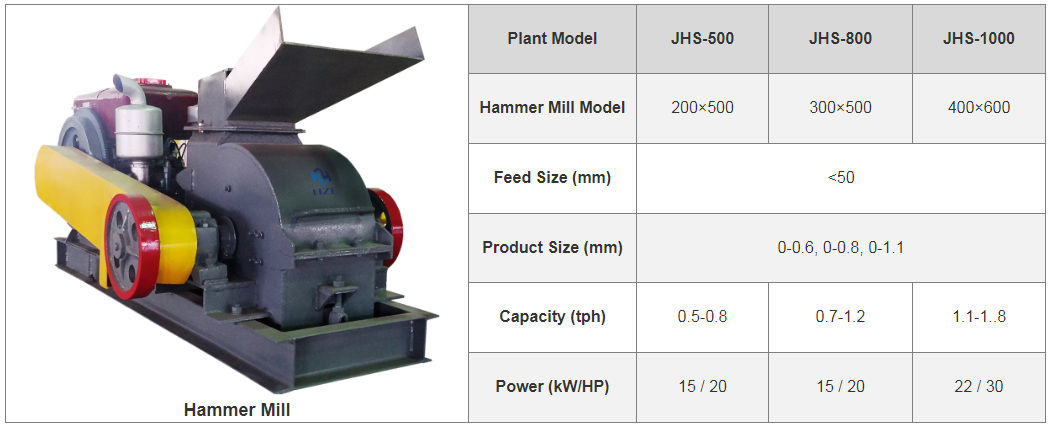

Parameters of Plant

Main Equipment

DOWNLOAD

DOWNLOAD