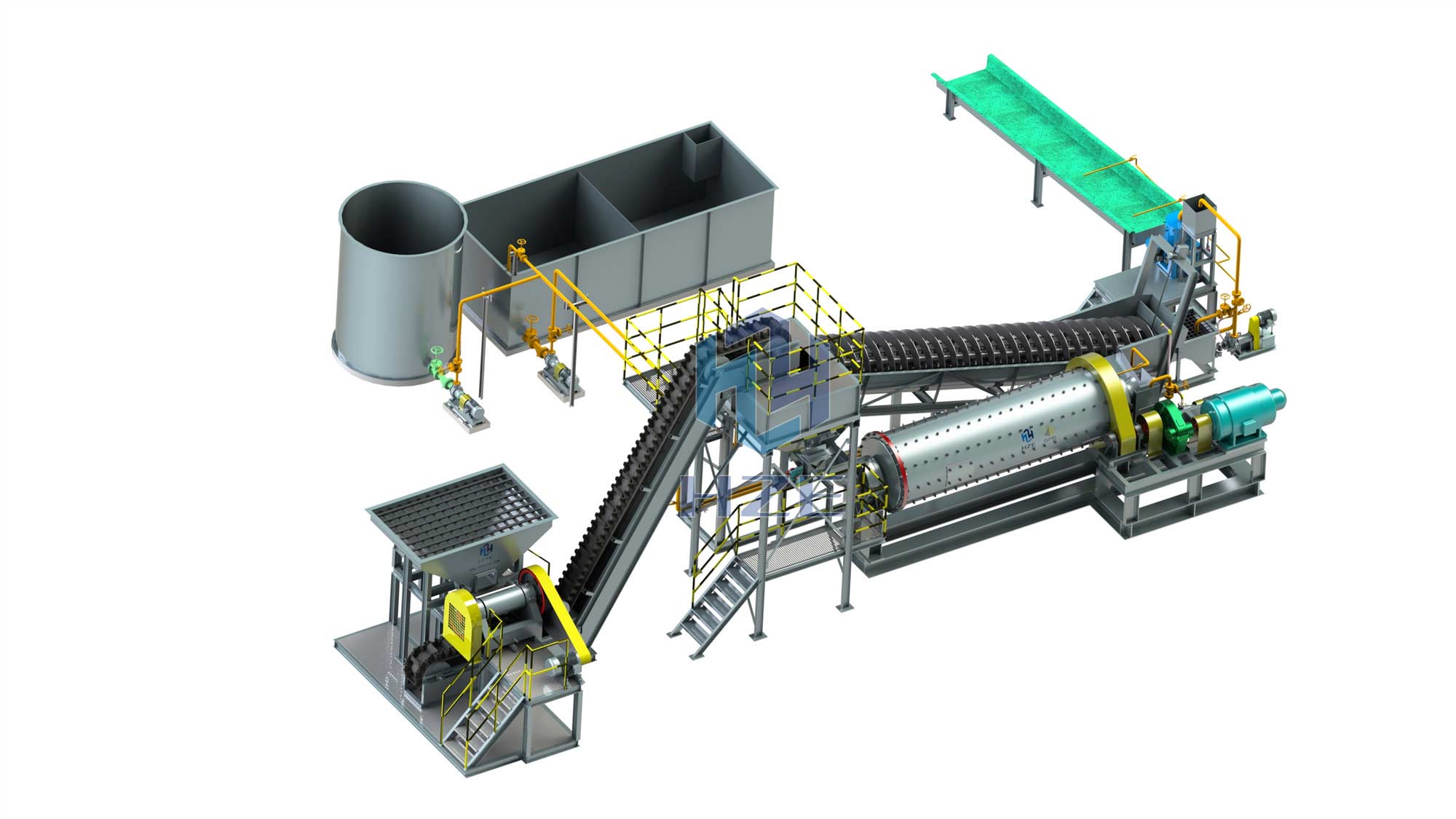

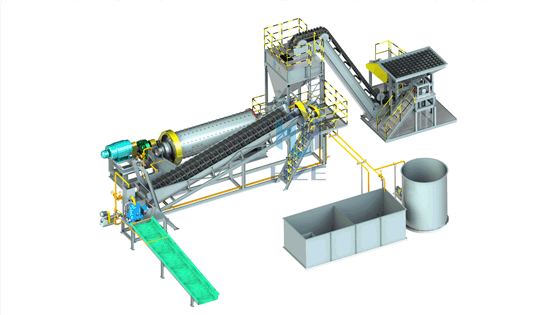

Small Scale Modular Gold Gravity Concentration Plant

APPLICATION

The relocatable modular gravity concentration plant recovers grained gold from the ores, especially for high grade ores.

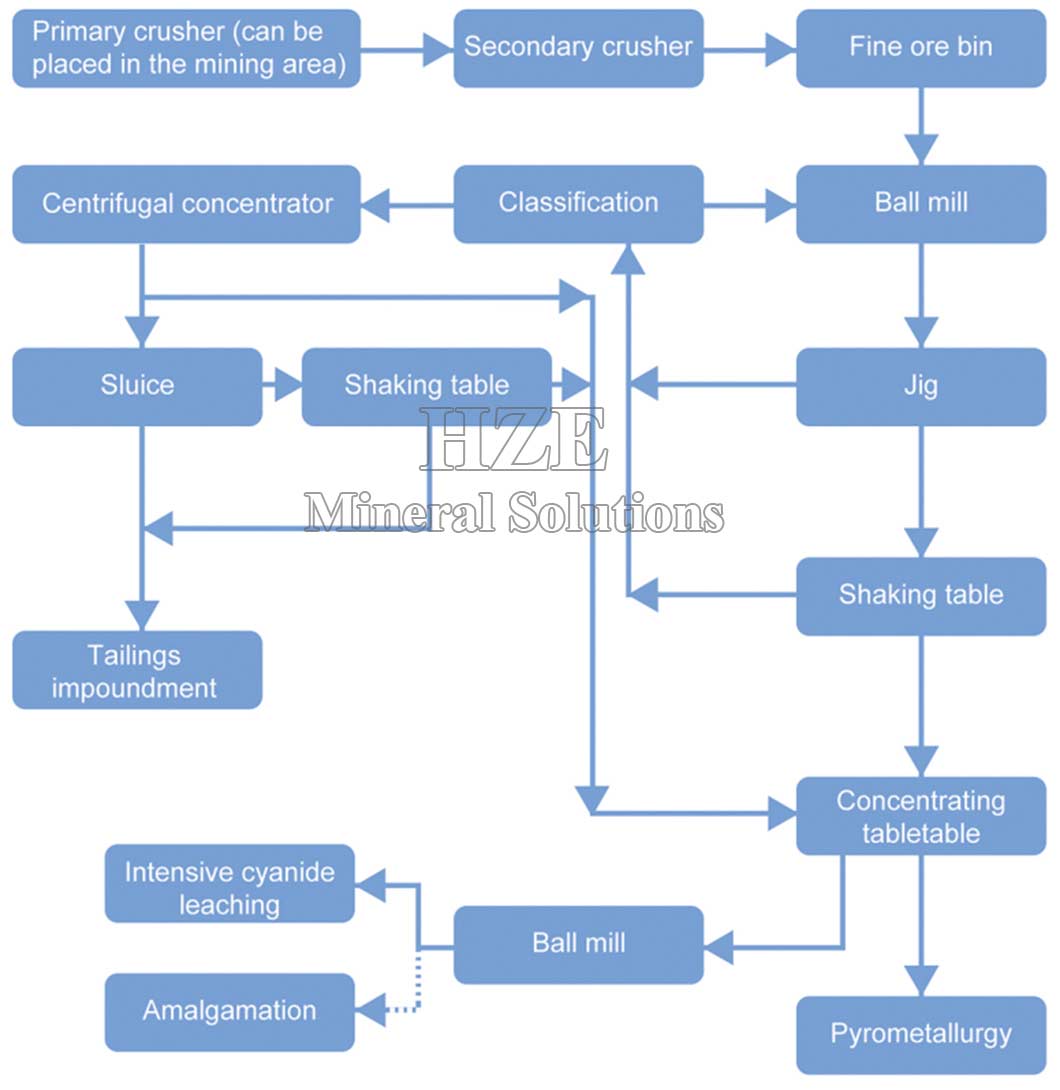

Main flowchart

Note: It is suggested that tailings of the concentrating table used as the cleaner should be collected and further grinded to - 325 mesh by a small ball mill to recover gold by intensive cyanide leaching at interval days. If mercury is allowed to be used in the country where the project is located, the tailings of the cleaner are grinded to - 150 mesh for amalgamation to recover gold. But amalgamation is not recommended process to recover gold for health and environment.

functional modules

For the situations of raw materials and the customer’s requirements, it is free to select the comminution module, grinding and classification unit, gravity concentration module, water supply module and power supply module to form a complete plant which recovers gold as much as possible. The equipment selection and arrangement of the gravity concentration module is freely defined according to the particle size distribution and occurrence status of gold.

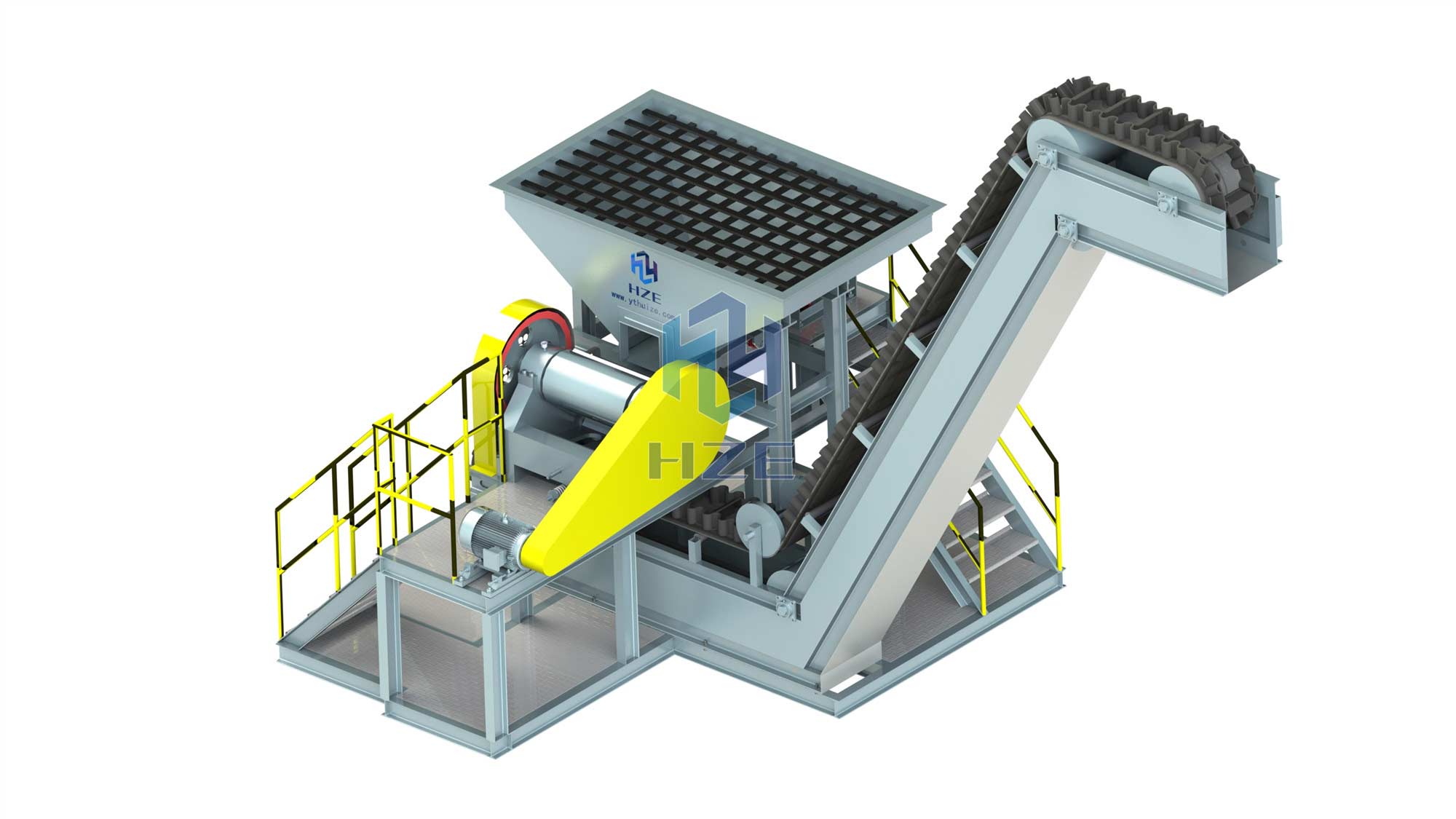

Crushing module

The rocks are crushed to the qualified particle size for grinding. The module is composed of hoppers, crushers, belt conveyors, feeders and so on.

The ores are usually crushed in two stages. According to the actual situation of the site, the primary crusher can be mounted in the mining area or the processing plant. The crusher is usually driven by a diesel engine if it is located in the mining area.

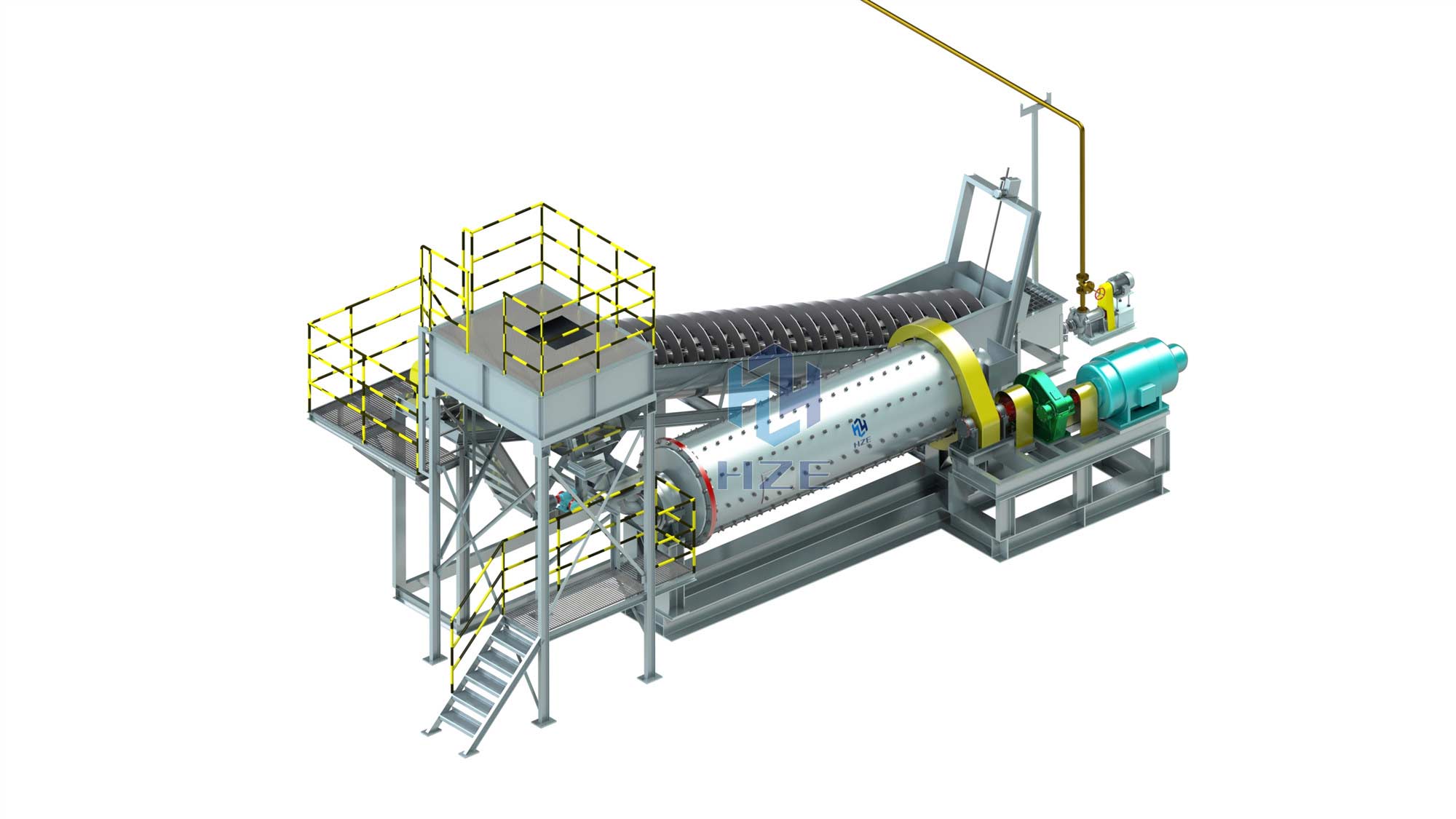

Grinding and classification unit

The closed-circuit grinding and classification system consisting of the ball mill and spiral classifier can liberate ore into the suitable particles for recovering free gold by gravity separation. The unit can be adjusted to a closed-circuit system consisting of the ball mill, slurry pump and hydrocyclone if the customer demands.

The grinding and classification unit is amounted in the whole steel frame.

Water supply module

It is composed of the water tanks, water pumps and water supply pipeline. The optimized water balance is achieved by the controlled the utilization rate of water.

Power supply module

It is composed of the diesel generators, distribution devices and the starting panels and so on. The module is suitable for the areas with inconvenient traffic and shortage of the power grid.

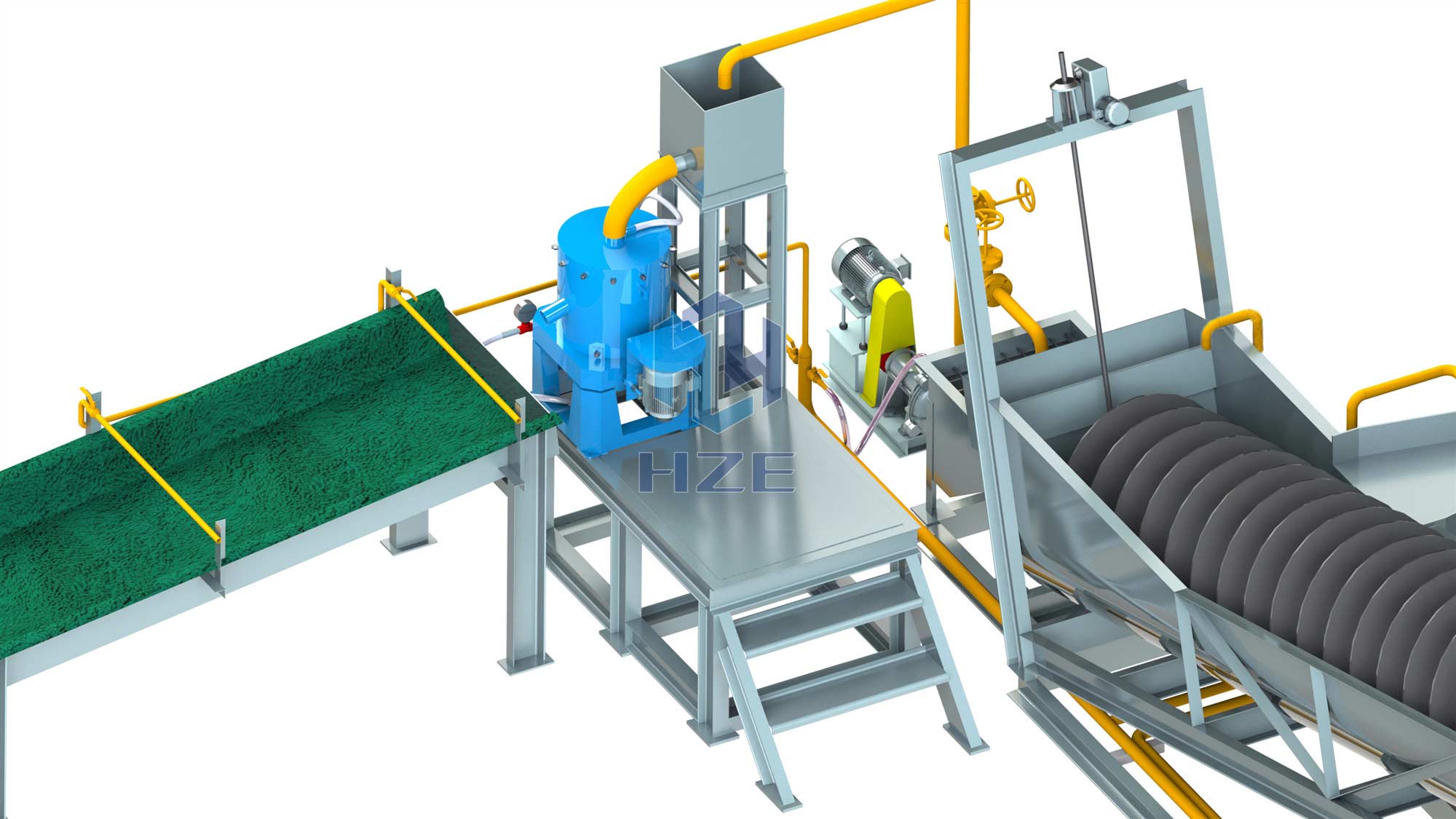

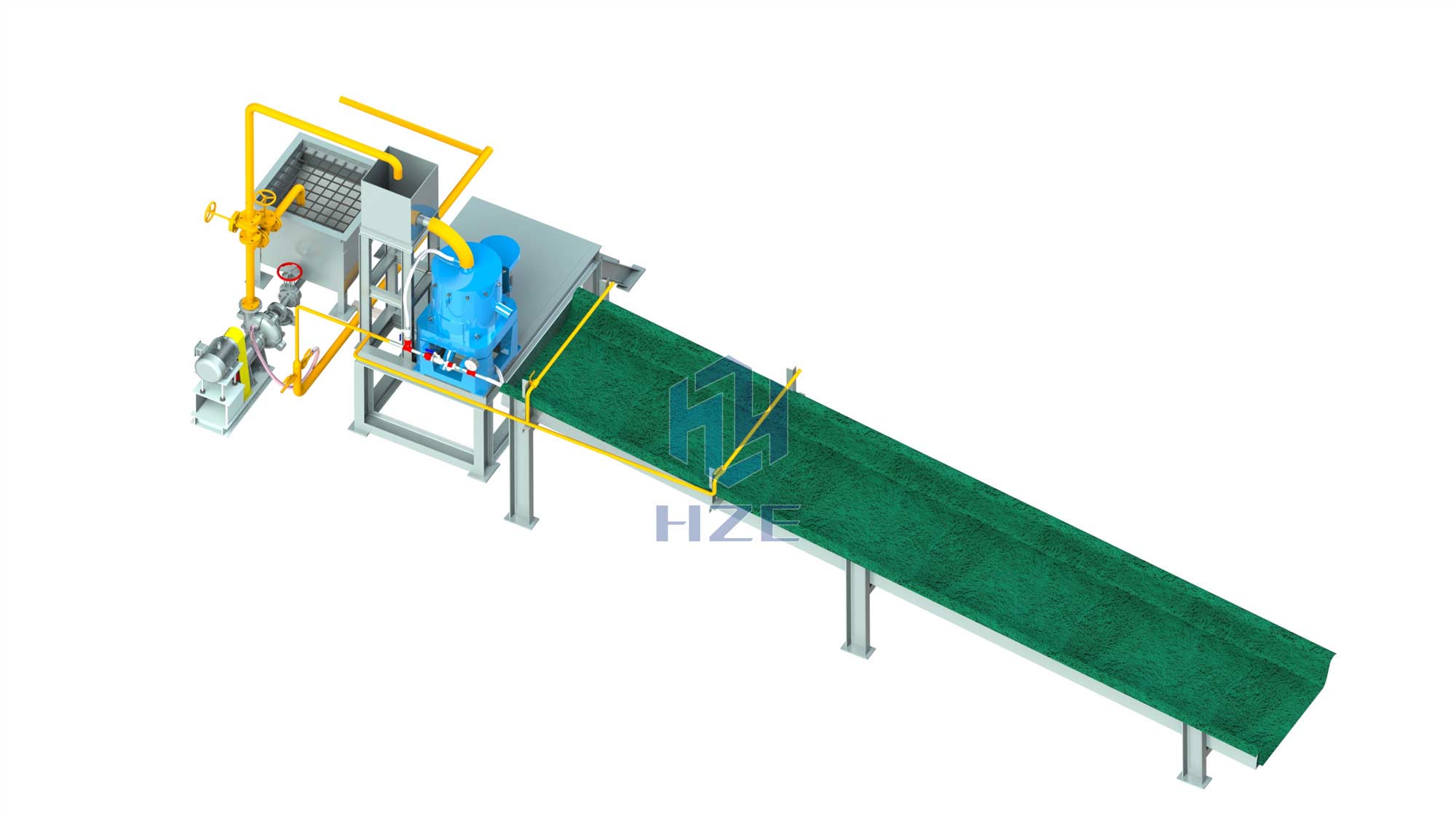

Special gravity concentration module

The coarse gold, fine gold and residual gold are recovered by the jig, centrifugal concentrator and sluice box in turn for the best recovery. The shaking table is used to improve the gold grade of the rough concentrate produced by the jig and sluice box. The concentrate of the shaking table and centrifugal concentrator is upgraded to very high grade by the concentrating table.

The concentrate of the concentrating table can be smelted and casted to the bullion bars directly. The tailings of the concentrating table has high grade gold, so it is re-grinded for intensive cyanide leaching and Merrill-Crowe process to recover gold.

Saw-tooth Wave Jig

This is a new type of energy saving and high efficient gravity separation equipment and developed based on the traditional jig. The pulsation curve of this kind of jig is saw-tooth wave shape which causes that upward flow is quicker than downward flow, i.e., the time of upward flow is shorter than the time of downward flow. It enhances the looseness of the bed, alleviates the inhalation effect, promotes the heavy mineral particles to settle fully, suits for a larger range of separation particles size, and greatly improves the separation ratio and recovery of the equipment. The water consumption will be saved 30-40% by this kind of jig comparing with the traditional jig. It is easy to install the jig, adjust the stroke, steplessly adjust the frequency by the frequency converter.

The jig is used as the first concentration equipment to recover the coarse grained gold.

Centrifugal Concentrator

The working principle of the centrifugal concentrator is that centrifuge force enlarges the gravity of the mineral particles to separate heavy and light particles. The key component of the separator is a conical concentration bowl with good wear resistance which rotates at high speed driven by the electric motor and is surrounded by pressurized recoil water. Slurry is fed from the top to the bottom of the conical concentration bowl. The concentration bowl has a series of the annular groove inside. The mineral particles are thrown to the annular grooves obliged by the centrifuge force generated by the rotation of the concentration bowl. During operation, only heavy particles can withstand recoil water to stay in the grooves and become the concentrate, the lighter particles flow upward and overflow out of the concentration bowl as tailings because they have less centrifuge force and can not withstand recoil water injected out of the grooves.

The equipment has remarkable effect on different particle size ranges of free gold, especially for fine gold particles to show excellent performance. After the equipment is installed after the jig in the gravity concentration module to improve the gold recovery more than 90%, and achieve the enrichment ratio to 1000 times.

Advantages and Characteristics:

1- High concentrating ratio and high recovery;

2- Steady recovery performance;

3- Environmentally friendly (no any chemicals required);

4- Low water and power consumption;

5- Low production costs, good part wear resistance and simple maintenance.

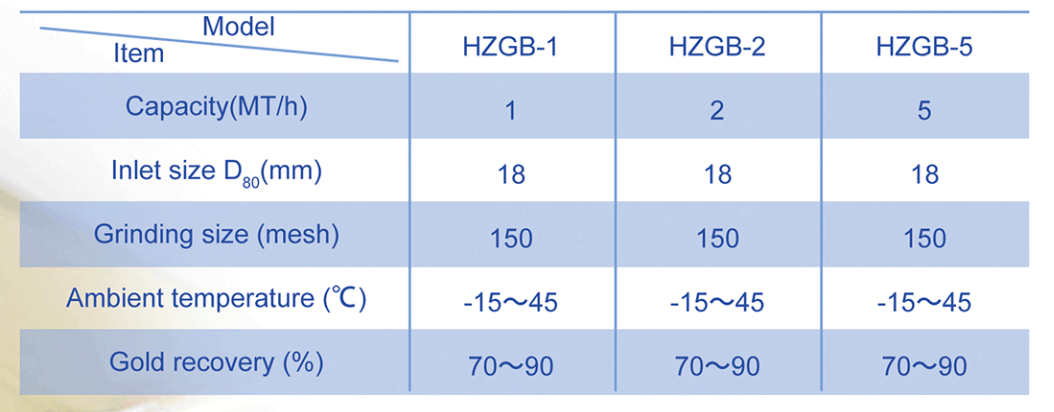

Specifications

advantages

(1) Maximizing the utilization of mineral resources ensures high recovery and economic benefits;

(2) The advanced technology and processing are adopted to get rid of the harmful chemicals such as mercury completely and protect human health and natural environment;

(3) Energy, water and consumables are saved, the number of operators is reduced, the capital of investment and the cost of production are decreased.

(4) Installation is fast, operation is easy, running is reliable, and different functional modules are combined freely to achieve the maximum recovery of gold.

(5) Minimal civil work requirements and the construction period reduced very much.

(6) It is easy to containerized, shipped or transferred to another location and reassembled, even in the most remote locations in the world.