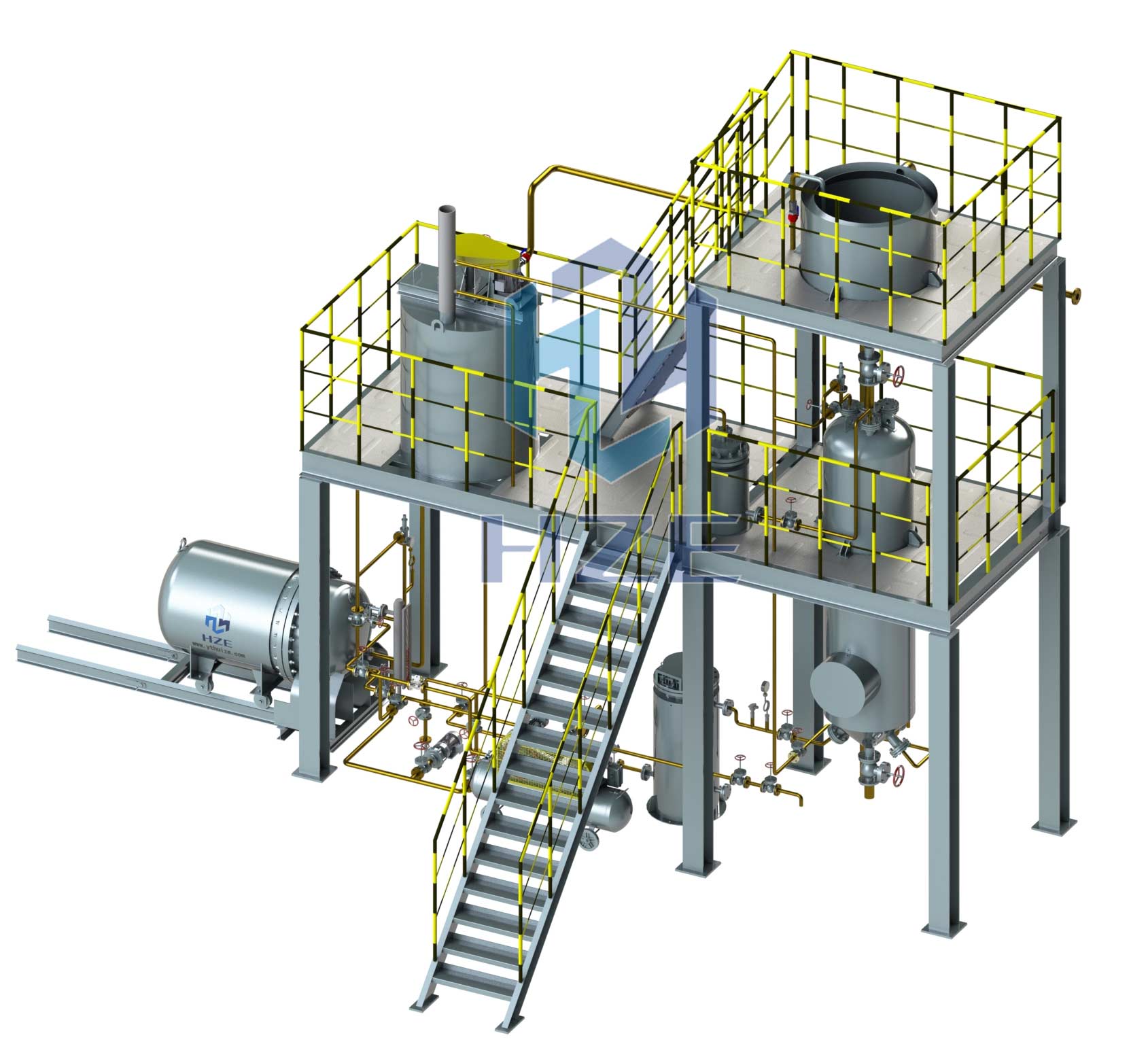

Gold or Silver Elution and Electrowinning System

Working Principle

Anions which are absorbed by activated carbon more easily are fed into solution for replacing Au (CN)2- out of surface of carbon to elute gold. Electrowinning recovers gold as sludge type from the pregnant solution produced by elution.

Features

High temperature, high pressure, cyanide-free and elution controlled automatically bring out the advantages of high efficiency, low consumption, and quick cycle.

High efficiency: the elution rate can be more than 96% while the grade of the gold loaded carbon reached 3000g/t, The grade of barren carbon can be reduced by 3-4 times than that of the conventional system.

Quick cycle: The working temperature of the system is 150℃so that elution is quick and the stripping duration is only 8-10 hours which is about one forth of that of the conventional system.

Low consumption: The elution Devices and electrowinning equipment compose a whole system. The temperature of every section of the whole system is same so that the heat exchanger is no need. The total power consumption is only 1/2-1/4 of the value of the conventional system because heat energy is recycled fully.

Cyanide-free: No sodium cyanide is fed to prepare stripping solution to realize low costs and no pollution.

High grade of gold sludge, no reverse electrowinning, easy to collect gold sludge.

Automation: Special liquid level control unit, temperature control unit and automatic control center.

Safety: Triple safety protection devices, i.e., self intelligent system, automatic rated pressure release system and safety valves.

Long life: The material type of equipment, pipes, valves and instruments is stainless steel.

Application

It is used to recover gold solid from gold loaded carbon coming from cyanide leaching.

Capacity

|

Standard Capacity of Process (kg/d) |

Upper Limit Capacity of Process (kg/d) |

Recommended model (kg/batch) |

|

300 |

750 |

HZ-200 |

|

450 |

1000 |

HZ-300 |

|

650 |

1700 |

HZ-450 |

|

750 |

1800 |

HZ-500 |

|

900 |

2200 |

HZ-600 |

|

1130 |

2700 |

HZ-750 |

|

1500 |

3600 |

HZ-1000 |

|

1800 |

4500 |

HZ-1200 |

|

2250 |

5500 |

HZ-1500 |

|

2700 |

6500 |

HZ-1800 |

|

3000 |

7500 |

HZ-2000 |

|

3750 |

9000 |

HZ-2500 |

|

4500 |

11000 |

HZ-3000 |

|

5200 |

13000 |

HZ-3500 |

|

6000 |

15000 |

HZ-4000 |

|

7500 |

18000 |

HZ-5000 |

Technical Parameters

|

Model |

Suitable Scale |

System Equipment List |

Operation Parameters |

|

|

Mineral ProcessingPlant Scale (t/d) |

Raw OreGrade (g/t) |

|||

|

HZ-200 |

<150 |

2-8 |

S1-Elution Column S2-Filter S3-Electrowinning Cell S4-Circulating Pump S5-Electric Heater S6-Carbon Ejector S7-Air Compressor S8- Elution Solution Preparation Tank S9-Clear Water Pump S10-Acid Storage Tank S11-Magnetic Pump S12-Carbon Storage Tank S15-Ccontrol Cabinet S16- Rectifier S17-Pickling Tank |

Desorption Solution:Ph≥13.5 Times Of Cycle: No limited Electrolysis Start: 100-110℃ Electrolysis Ending: 150℃ Electrolysis Current: 350-1250a Electrolysis Pressure: 2-4v

|

|

HZ-300 |

150-300 |

2-8 |

||

|

HZ-450 |

||||

|

HZ-500 |

300-500 |

|||

|

HZ-600 |

||||

|

HZ-750 |

||||

|

HZ-1000 |

500-1000 |

|||

|

HZ-1200 |

||||

|

HZ-1500 |

||||

|

HZ-1800 |

||||

|

HZ-2000 |

1000-2000 |

2-20 |

||

|

HZ-2500 |

||||

|

HZ-3000 |

||||

|

HZ-3500 |

2000-3000 |

|||

|

HZ-4000 |

||||

|

HZ-5000 |

||||

|

Special Type |

>3000 |

|||